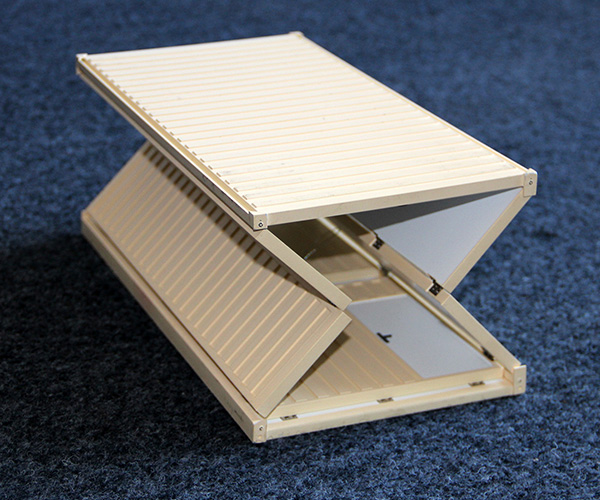

The folding container house adopts modular design technology, which can be designed and produced according to customers' preferences. The size supports customisation, saving space and transportation costs. Fire rating A, earthquake resistant, windproof, leak proof, foldable, reusable, in compliance with emergency living standards.

Installation only requires simple tools such as wrenches, bolt drivers, etc., which are simple, fast, and flexible in design. For people who need space but have limited space and access, and need to frequently move construction sites or houses or temporarily use houses, foldable container houses are the perfect solution.

The high-end folding corrugated house is an upgrade based on the folding packing box, and all materials are made of more sturdy and durable galvanised materials. The overall framework coating adopts electrostatic anti-corrosion spraying technology.

Advantages:

1. The thickness of the overall wall has been increased to 75m, which better enhances the insulation and durability of the house, and all 28 hinges at the folding point have been upgraded to high-strength hinges for connection.

2. The top of the box room adopts a drainage channel design, which can better achieve organized drainage and prevent rainwater from being blown into the room through the folding point by the wind. We have obtained a patent for this design.

3. All the frames of the corrugated house have been upgraded to thicker and stronger materials, greatly improving its wind resistance and snow resistance.

4. The corrugated room power supply uses aviation plugs, which can be wired in an organized manner to avoid the occurrence of short circuits.

5. All the gaps in the corrugated house are glued with sealing strips, which better enhance the sealing of the house.

| Basic feature | External dimensions(mm) | 5800length x 2480width x 2520height |

| Internal dimensions(mm) | 5640length x 2320width x 2340height | |

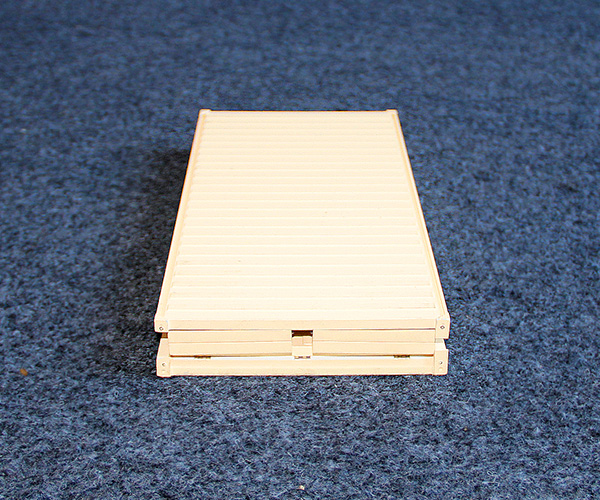

| Folded state | 5800 x 2480 x 580 mm | |

| Total weight | 1200 kg | |

| Frame structure | Top main beam | Q235B rectangular square tube 60 x 80 x 1.3mm |

| Bottom main beam | Q235B rectangular square tube 80 x 140 x 1.3mm | |

| Front and rear main beams | Q235B irregular square tube 60 x 80 x 1.3mm | |

| Side wallframe | Q235B P-type square tube 60 x 80 x 1.3mm | |

| Bottom load-bearing capacity | Q235B rectangular square tube 40 x 40 x 1.2mm | |

| Top load-bearing capacity | Q235B rectangular square tube 40 x 40 x 1.2mm | |

| Hanging head | Q235B 50 x 130 x 6mm | |

| Folding hinges | Galvanized hinges 13mm | |

| Box top | Overall framework protection coating | Electrostatic spraying/high gloss white |

| External roof panel | Corrugated board 0.4mm | |

| Internal ceiling | Color steel veneer V193*0.25mm | |

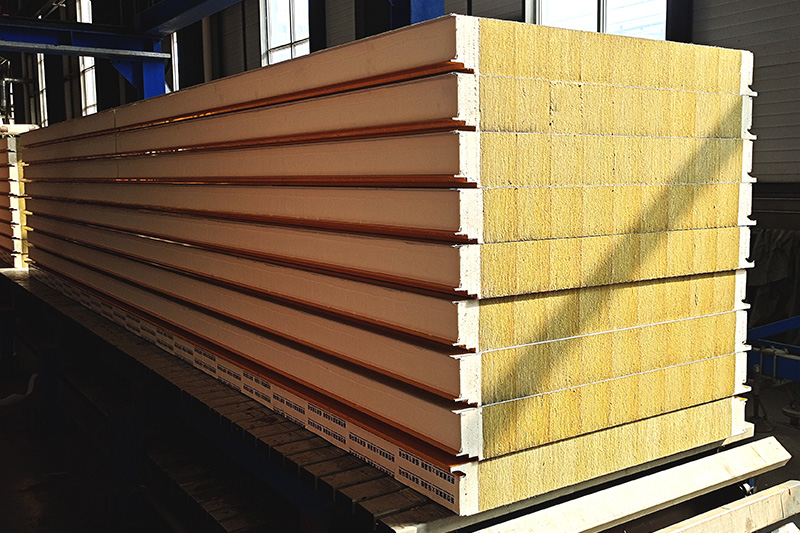

| Wallboard | Insulated glass wool | Glass wool roll 5 0mm(bulk density 16kg) |

| Side wall | 65mm composite board 0.23mm+basalt Wool(bulk density 50kg)+-0.1mm |

|

| Front and rear wall panels | 65mm composite board 0.23mm+basalt Wool(bulk density 50kg)+-0.1mm |

|

| Floor | Waterproof fiber cement board floor 18mm | |

| Electrical system | Electrical wiring must be installed strictly in accordance with moisture-proof standards and allelectrical products must comply with CE certification. Connect circuits according to circuit engineering specifications. Indoor: incoming 4²GB standard soft copper wire, 120A circuit breaker, socket incoming 2.52, 1 five hole single socket, 1 air conditioning socket and 1 long LED light | |

| Ordinary anti-theft door | High quality anti-theft door (warm white) size: 970mm x 1970mm | |

| Window | 930 x 930 plastic steel anti-theft integrated window, glass thickness 4mm(warm white) | |

| Quality assurance | The whole box meets the A-level fire protection standard as a whole | |