Talking about the steel structure technology of large stadiums

- 20 Oct 2020

- steel structure

This article takes the project overview and characteristics of the China National Stadium and Guangzhou Stadium as the research object. Due to its advanced installation and construction technology, and after a certain scientific measurement and positioning, it has improved the construction quality and construction efficiency of the project, and solved These large-scale gymnasiums had a tight schedule and successfully completed the construction tasks.

Large-scale stadiums generally have the comprehensive characteristics of large span, high precision, and very complex steel structure, so their construction is very difficult. The construction needs to go through a rigorous and sufficient preparation process, and increase technical support and personnel support during construction. Give full play to the huge role of large stadiums in expanding social and market benefits. Generally speaking, due to the limitations of technology and construction environment, the project faces huge problems and challenges in construction and other aspects. This article selects the National Stadium and Guangzhou Stadium as the research Objects, first introduced the construction status and key difficulties of the two large stadium projects, and briefly introduced the construction status of the steel structure roof truss installation project of the main stadium. From the construction process and implementation results, comprehensively monitor whether the steel structure plan of the project can meet the construction needs and proceed scientifically.

1. The construction status of the steel structure technology of the National Stadium

The National Stadium is the venue for Olympic handball, gymnastics and other events. It is one of the three main venues in the Beijing Olympic Center. As an internationally advanced large-scale stadium, in order to fully reflect the spirit of the Olympic host that is green, environmentally friendly and thrifty, Under the premise of meeting the building function and appearance, the building structure should be designed reasonably, and the safety issues inside the gymnasium should be better considered. After completion, it will become the largest two-way string truss structure of its kind in the world. The steel roof structure of the National Stadium will be a single-curved two-way string truss structure, the upper chord will be an orthogonal normal laying plane truss, and the lower chord will be prestressed. The cable passes through the two-way cable clamp node at the lower end of the steel brace to form a two-way spatial tension cable network.

The overall structure of the gymnasium consists of a competition area, a warm-up area, peripheral annexes, and an underground garage. In the structural system of the gymnasium, the lower chord of the roof structure of the competition area is equipped with steel cables at each horizontal and some parts of the longitudinal position. The middle brace and the upper grid structure form a structural form with a certain vertical rigidity and self-carrying capacity. , This constitutes the overall spatial structure of the stadium roof. In terms of force, the engineering two-way string truss has the dual characteristics of two-way cross truss and prestressed structure. The truss is supported on four sides and belongs to a typical spatial two-way force transmission system. In terms of internal force distribution, the bending moment in the middle of the slab is large, and the support The bending moment is small, the lateral force is large on the short side, and the longitudinal force is small on the long side. The corners and nearby supports are affected by the overall structure and keep them in tension. The value of the prestress of the steel cable decreases from the central part to the two sides, and the distribution of the cable section and the prestress value is consistent with the internal force distribution of the orthogonal truss. The tension cable has a great effect on the overall structure of the truss and the structural performance of the overall stadium steel structure. The tensile force of the corner support of the structure is reduced, the cable force during the tensioning process is very high and the safety performance is high. In the roof structure, the lower chord is arranged with 9-22 shafts and 8 shafts in the transverse direction and 8 shafts in the longitudinal direction. The longitudinal cables are single cables, and the horizontal cables are under the double cable structure. The longitudinal side 5 truss is not cabled, and the horizontal side 2 is not cabled. The upper end of the round tube brace is connected with the lower chord of the truss structure by universal spherical hinge nodes, the lower end is connected with the cable by a splint node, and the connection between the cable end and the steel structure is designed as a cast steel node.

2. Construction status of steel structure technology in Guangzhou Gymnasium

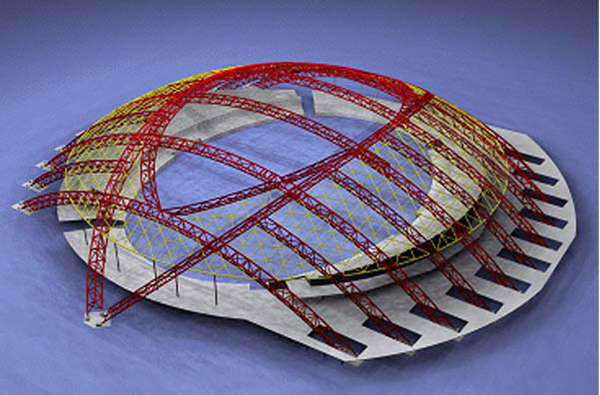

The Guangzhou Gymnasium is the main venue for the Ninth National Games. It is currently the steel structure roof of the gymnasium with the largest span in China. It consists of the main stadium, training hall, and mass activity center. It is a reinforced concrete structure with a longitudinal main truss and a radial truss. , Peripheral box-shaped horizontal steel ring beam and supporting cables. Before the construction, the structure simulation technology was adopted, and the simulation calculation was carried out for each working condition of the installation plan. During the construction, temporary steel supports were set up, hoisted in sections, and spliced at high altitude.

The difficulty in the construction of the Guangzhou Gymnasium is firstly in terms of its force. The force status of its various components is different from the design force status, and construction needs to be carried out after calculation; secondly, hoisting can only be carried out off-site, which is difficult and poor component stability ; Finally, the pre-stressed steel cables are more, the tension is small and mutual influence, which increases the difficulty of construction. Therefore, in the construction, Guangzhou Gymnasium chose two 250t reinforced crawler cranes to carry out the lifting task of the components in the selection of hoisting equipment. When installing the steel ring beam, first divide it into sections, and then directly The hoisting is in place, and the welding is performed after the overall closing adjustment. When installing the main truss, the construction method of segmented hoisting and high-altitude splicing is adopted. First, the main truss is segmented by setting temporary steel supports. And use a large crawler crane to lift each section to the space splicing on the steel support. And through the design of a special adjustment structure, each section of the main truss is hoisted in place, and welded and fixed after being accurately in place to ensure the smooth installation of the main truss.

3. The characteristics and construction points of the steel structure of the gymnasium

The gymnasium is a large-span building, and its own shape, function, purpose, use conditions and other factors determine that its structural scheme can adopt beam, frame, spherical grid and suspension-cable type internal and external shapes. The building of the gymnasium Using high-strength steel, the shape and structure are generally very individual, and attention should be paid to the construction problems of the roof truss, hanging ceiling and other building parts. Therefore, in the construction of the gymnasium, when the temporary support system of the steel structure is installed, the method of erecting the full-floor scaffolding is generally used. However, in the construction of the steel structure with a large span such as the gymnasium, two circles of shellfish are generally used. As a means of support, mine scaffolding not only satisfies the function of the gymnasium, but also lays a solid foundation for the subsequent installation of steel components and pre-stressed construction, and to a large extent effectively solves the problem of using the full house scaffolding method.

In the layered, graded and batched tensioning implementation plan, first determine the layered tensioning sequence, choose the method of tensioning the outer steel cable first and then the inner steel cable or tensioning the inner steel cable first and then the outer In this technique, the direction of force transmission is the direction of the inner structure of the roof truss → outer structure → structural beams and columns → foundation, and the inner support point is on the top of the upper chord steel beam of the outer layer, and the inner layer is prestressed The application of the prestress does not have a huge impact on the outer structure, so when the prestress is applied, the outer layer is generally rigid, and then the inner cable is stretched; when determining the graded tension, the error value and grading of the prestress are generally considered The effect and influence of tension on the overall appearance and shape of the steel roof truss; when determining the batch tension, it should be ensured that the tension force of each batch of steel cables can be symmetrically arranged during tension, and finally the degree of mutual influence of tension needs to be determined. It is necessary to use ansys software to first analyze the entire construction process, mainly to analyze the layered, hierarchical, batch, and synchronous symmetrical tensioning process, and finally obtain the cable force and the steel roof truss under the tension of the inner and outer layers. The theoretical data such as the camber value, combined with the actual project, put it into the concrete engineering design. Construction monitoring is the foundation of engineering construction control and an important means to ensure that the structure is safe during the construction process and meets the design requirements. Therefore, the establishment of a complete construction monitoring system in the large-span steel structure construction of the stadium is also one of the important aspects of construction technology. Construction monitoring mainly includes deformation monitoring, stress monitoring, temperature measurement and other supervision methods. Deformation monitoring generally refers to the use of rangefinders, levelers and other tools to carry out corresponding control observations on each key node of the steel structure. Stress monitoring refers to the use of steel string sensors or high-tech fiber grating sensing technology to achieve remote monitoring; temperature measurement refers to the use of radiation temperature measurement, resistance thermometer temperature measurement, thermocouple temperature measurement and other methods Long-distance monitoring activities.

In short, the steel structure engineering of large-scale stadiums is getting more and more attention, and the large-span steel structure stadiums are facing various challenges in technology and other issues. Through the analysis of the steel structure construction characteristics of the National Stadium and Guangzhou Stadium, it is hoped that steel Provide some help for structural construction and other issues.