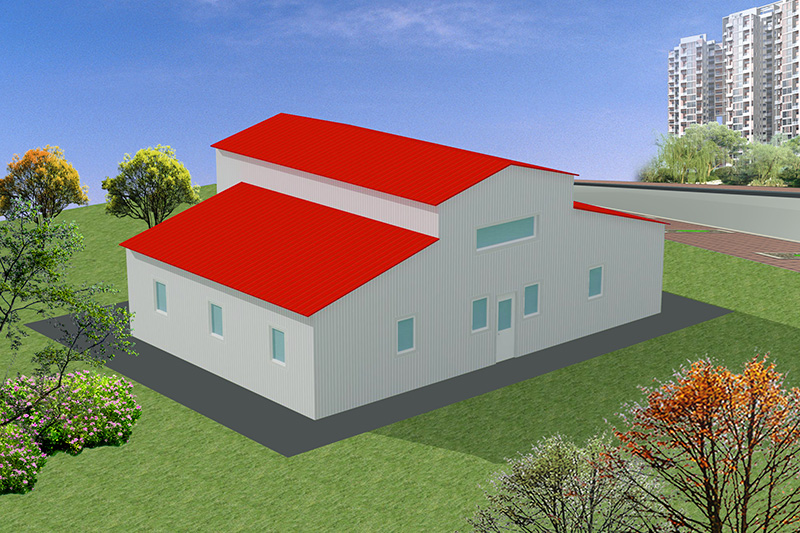

Steel structure workshop introduction

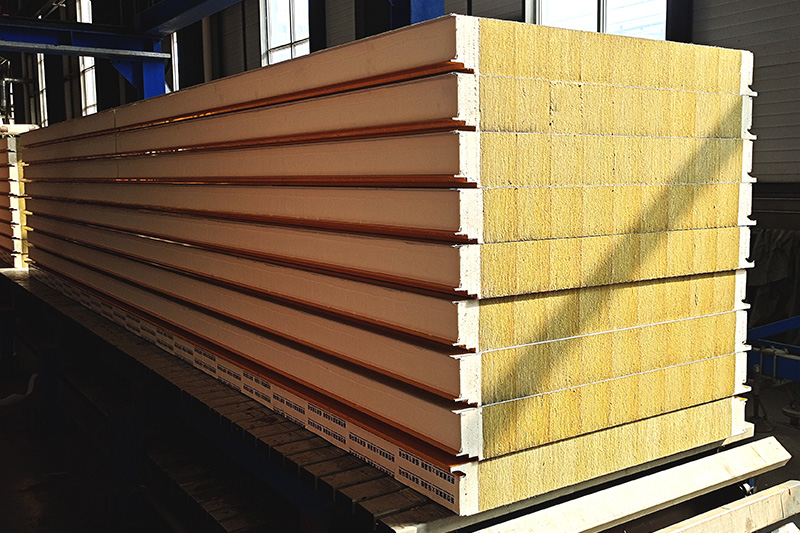

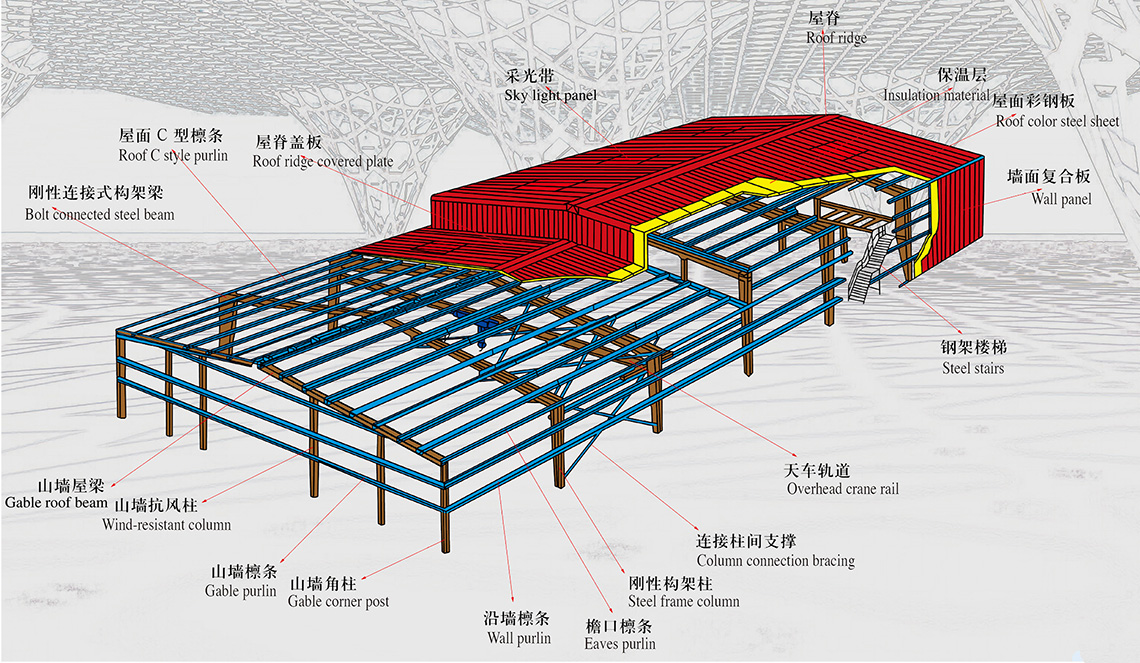

The steel structure workshop building is mainly composed of steel materials bearing members such as section steel, steel plate and external wall and roof maintenance system. Steel structure includes steel columns, steel beams, purlins and other components. The external wall and roof maintenance system adopts color steel sandwich panel and other new building materials, as well as bricks. Welding, bolt or rivet are usually used to connect each component or part.

Application:

Widely used in factories, warehouses, office buildings, shopping malls, gymnasiums, hangars and so on;It is not only suitable for single-storey large-span buildings, but also for multi-storey or high-rise buildings.

Features of steel structure workshop

1. Light weight, high strength and large span: The weight of the house constructed with steel structure is about 1/2 of that of reinforced concrete house; It meets the need of large space of the house, and the use area is about 4% higher than that of reinforced concrete house.

2. Simple construction and short construction period: All the components are prefabricated in the factory. It just needs simple assembly at the site, thus greatly shortening the construction period. A building of 6000 square meters can be basically installed and completed in 40 days.

3. Durable and easy to repair: Steel structures designed by computers can resist bad weather and just require simple maintenance.

4. Beautiful and practical, reasonable cost: Steel structure building lines are simple and smooth with a sense of modernity. Coloured wall panels have a variety of colours to choose from. And other materials can also be used in the wall, so they are more flexible. Steel structure is lighter in weight, lower in cost of foundation, faster in construction. And its comprehensive economic benefit is much better than that of concrete structure.

5. Easy to move, recycling without pollution: Steel structures can be disassembled and assembled many times. And there will be less environmental pollution during construction and demolition.

Installation procedure of steel structure:

1. Foundation embedded bolt installation

2. Steel column installation (column bracing installation at the same time)

3. Steel beam installation (roof support installation at the same time)

4. Crane beam installation

5. Roof purlin installation

6. Wall purlin installation

7. Roof panel installation

8. Wall panel installation

9. Enclosure and edge installation

10. Completion

Manufacturing Process of Steel Structure

Cutting

The cutting procedure mainly uses advanced CNC cutting machines, scattered plates cutting uses plate shearing machining and semi-automatic cutter machine. Before cutting, rust and dirtiness must be cleaned out of cutting area of the steel plate. So it is the dross and splash on the plate after cutting. The material of steel structure is mainly, GB-Q235(ASTM-A36, JIS-SS41, JIS-SM41, DIN-St37), GB-Q345(ASTM-A441, JIS-SS50, DIN-St52).

Assemblage

H section steel is welded by automatic assemblage machine, before assembling all parts and components should be passed special inspection, and the rust and dirtiness on the welding area 30-50mm will be cleaned out. Assemblage precision all reach China standards GB50205-2001.

Welding

There must be evaluation report about all the steel materials, welding materials, welding methods and hot treatment, and then determined the welding craft to meet national standard GBJ81-91. All the welders has passed the examination and got certification. Remove greasy dirt and rust on solder wire before using, and cure the solder wire and welding rod based on instructions. The external side of welding seam conform to china standard and GB11345-89.

Correction

Cold correction and cold bending are not allowed when the environment temperature lower than -16℃ for carbon steel, -12℃ for low-alloy steel. When the carbon steel and low-alloy steel were heated for correction and bending, the temperature are kept not exceeding 900℃. After correction there is no significant dents and damage on the steel surface. The scratch depth is less than 0.5mm. Steel structure correction tolerance conformed to China standard GB50205-2001.

Assembly (Manual Welding)

The spacing between H type flange plate splicing seam and web splicing seam should not be less than 200 mm. The length of flange plate splicing should not be less than 2 times the width of plate. The width of web splicing should not be less than 300 mm and the length should not be less than 600 mm.

Shot Blasting

The rust on the steel components surface need to be cleaned out before coating, and the coating quality depends on rust cleaned level. We can reach the high technology requirement by big shot blasting machine, so that the components can meet Sa3 grade in rust clearance standard. There are several big cleaned chambers in the shot blasting machine, which can meet the requirement of steel parts and H type steel surface treatment.