Design of multi story and high rise steel structure

- 19 Sep 2020

- steel structure

Civil buildings with less than ten stories and a total height of less than 24m and industrial buildings with six stories or less and a total height of less than 40m are defined as multi-layer steel structure; those with more than the above height are defined as high-rise steel structures.

Light frame and light frame-supporting steel structure are suitable for multi-story civil buildings and industrial buildings with floor equivalent live load less than 8KN/m2 and building height less than 20m.

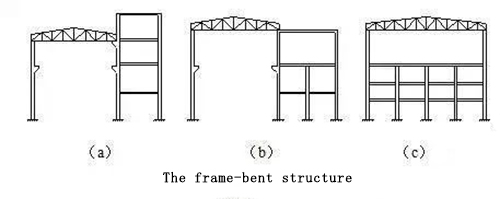

The frame-bent structure can be divided into lateral frame-bent and vertical frame-bent. The lateral frame-bent is composed of the bent frame and the frame laterally connected, and is divided into equal height and unequal height. As shown in Figures (a) and (b), the upper part of the vertical frame-bent structure is a bent structure, and the lower part is a frame structure, as shown in Figure (c).

Among the units that make up the structural system, in addition to the clear form of the frame, the forms of supports, shear walls, and cylinders are relatively rich. The structural system classification table specifically lists the commonly used forms. Among them, the energy dissipation support is generally used in the frame-support structure of the center support, and can also be used in the ordinary truss tube or the oblique grid tube forming the cylindrical structure. Not used at the same time; the skew grid cylinder is entirely woven by crossed diagonal bars, which can provide great rigidity.

Mega structure is a relatively broad concept. When vertical load or horizontal load is transmitted in the structure with multiple floors as its basic scale instead of one floor in the traditional sense, it can be regarded as a mega structure.

For example, a part of a frame or truss is regarded as a single composite member, and a giant beam or column is formed with the scale of a layer or a span as the "section" height, thereby forming a giant frame system, which is a giant frame structure, a secondary structure between giant beams The vertical loads are all transferred to the mega-column through the mega-beam in sections; the mega-supports are set up between the nodes of the “mega-beam” and “mega-column” of the mega-frame to form a mega-frame-support structure; when the frame is of ordinary scale, When the supporting arrangement is based on the building's facade, it can be called a giant supporting structure.

Due to the different characteristics of force and deformation, the ductility of the structural system is also quite different. The ductility of the structural system with multiple lines of defense against lateral force and non-buckling failure is higher; at the same time, the ductility of the structure also depends on whether the node area will be brittle failure occurs and whether the plastic zone of the component has sufficient ductility.

In the system classification listed, frame-eccentric support structure, frame-center support structure with energy dissipation support, frame-seismic wall structure with steel plate wall, tube-in-tube and beam-tube structure without diagonal grid tube, generally High ductility grade structure type; all cylinders adopt oblique grid cylinders, generally low ductility grade structure type.

The structure with higher ductility can withstand greater deformation in the plastic stage without component buckling and overall collapse, so it has better energy dissipation capacity. If the fortification intensity is used, the structure should have the ability to absorb seismic energy in the same amount as earthquake resistance Design criteria, the higher ductility structure should be able to allow the lower ductility structure to enter plasticity earlier.

The buckling restraint support can improve the ductility of the structure, and its ductility is more controllable than the frame-eccentric support structure. Therefore, depending on the proportion of the total support, the applicable height of the frame-center support structure can be increased by up to 20%.

The dual anti-side force system refers to the structural system with two anti-side force lines of defense, in which the horizontal bearing capacity of the second line of defense is not less than 25% of the total horizontal shear force.

Both the outrigger truss and the peripheral truss can increase the lateral contribution of the surrounding frame. When the two are installed at the same time, the effect is more obvious. It is generally used for frame-tube structures, and can also be used for various kinds of needs to improve the lateral contribution of surrounding members. In the structural system. The upper and lower chords of the outrigger truss must be pulled through within the barrel, and at the same time, sufficient diagonal braces or shear walls are set in the barrel between the chords to facilitate the self-balance of the axial force of the upper and lower chords in the barrel. The number and location of outrigger trusses should not only consider their overall anti-side efficiency, but also the bearing capacity of the connected members and nodes.

For super high-rise steel structures, wind loads often play a controlling role, and it is of great significance to choose a shape with a small wind pressure; under certain conditions, the cross-wind vibration effect of the structure caused by eddy current shedding is very significant. The structure is flat, the selection of the facade and the angle The partial treatment will have a significant impact on the cross-wind vibration, and the cross-wind vibration effect of wind-sensitive structures should be studied through aeroelastic model wind tunnel test or numerical simulation.

When multi-story steel structures are set up with basements, the houses are generally tall, and the steel frame columns should extend to the basement level. In the frame-support structure, the supports arranged continuously in the vertical direction, in order to avoid the formation of sudden changes in stiffness at the bottom layer with the greatest seismic response, which is disadvantageous to earthquake resistance, the supports need to be extended to the basement.

At present, the commonly used slab forms and methods with good seismic performance of multi-storey steel structure houses. When the assembled integral reinforced concrete floor is adopted, embedded parts can be arranged at the end of the precast concrete floor slab rib, and the steel beam can be welded firmly after installation to ensure the integrity of the floor. For super high-rise steel structures, if conditions permit, lightweight aggregate concrete should be given priority to floor concrete. Under the condition of ensuring the reliable connection between the floor and the beam, the two-end hinged floor beam can generally be designed as a composite beam.

Since the comfort of the human body is a relatively complicated issue, there are large deviations between individuals. When the owners require higher service standards, they can increase the requirements for this value. If necessary, the comfort of the structure can be improved by installing vibration damping devices such as TMD and AMD.