Anti-cold bridge measures for steel structure roof engineering

- 31 Aug 2020

- steel structure

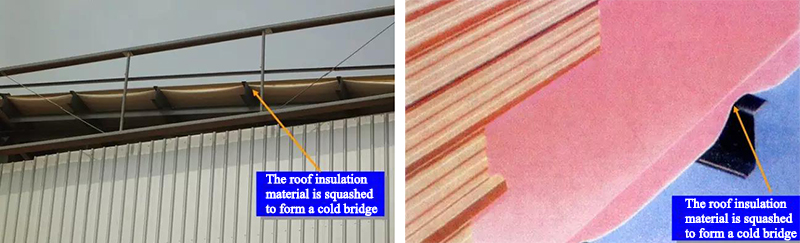

Common steel structure roof node: purlin cold bridge

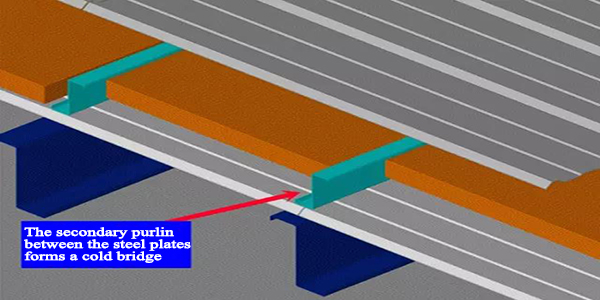

Common double-layer steel plate roof node: secondary purlin cold bridge

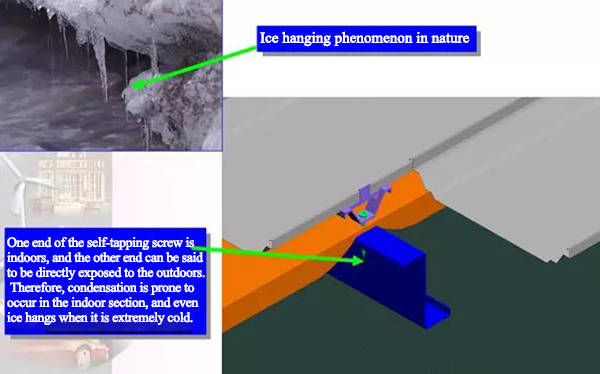

Common steel structure roof: self-tapping screw cold bridge

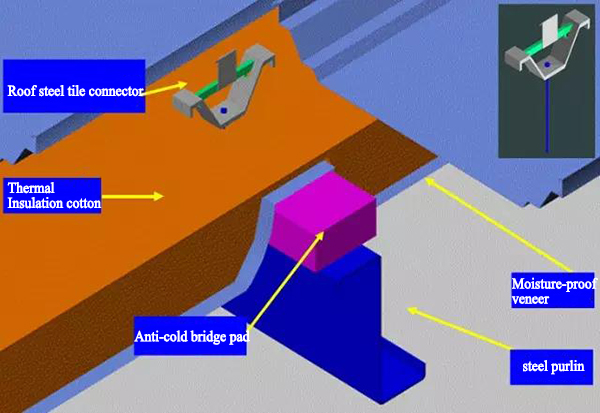

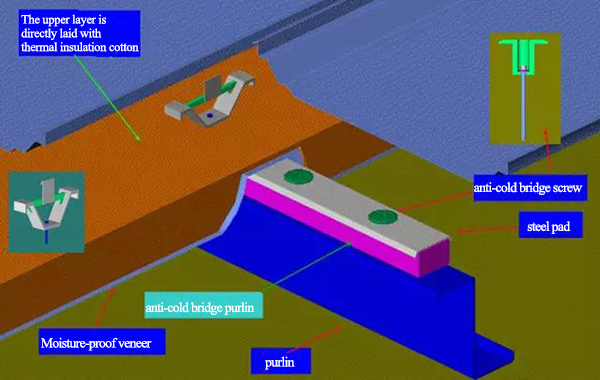

Single-layer steel plate roof plan 1 : node:anti-cold bridge pad

Single-layer steel plate roof plan 2: Anti-cold bridge pad + anti-cold bridge nail, completely solve the problem of condensation

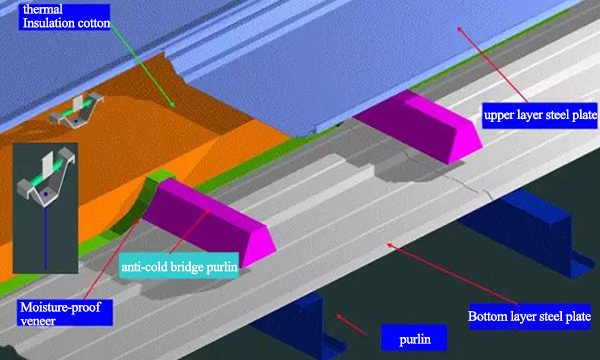

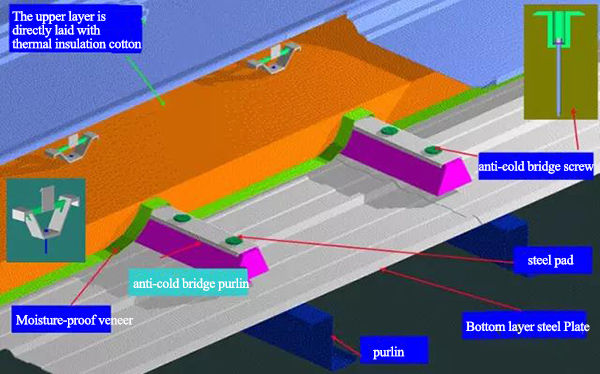

double-layer steel plate roof plan 1: anti-cold bridge purlin

double-layer steel plate roof plan 2: Anti-cold bridge purlin + anti-cold bridge screw, completely solve the problem of condensation

How to solve the condensation of indoor color steel plate?

Solution: make a good heat-insulation layer, eliminate water vapor, and there is no cold bridge between the indoor wall and the outdoor

1. The reason of condensation is that the temperature of the board is lower than the dew point (the temperature when condensation occurs) and there is water vapor in the room.

The solution is to increase the heat preservation effect, so that the temperature difference between the board surface and the indoor room is generally within 3 degrees.

2 Glass wool absorbs a lot of water, and the heat preservation effect is greatly reduced after water absorption.

It is recommended to make a vapor barrier (that is, laminated aluminum foil or white polypropylene veneer, which is required to face indoors) to prevent water vapor from entering the insulation layer. And increase the insulation thickness, generally by 1.7 times.

3. Increase ventilation: Ventilation will lower the room temperature, reduce the temperature difference on the surface of the board, and reduce the relative humidity in the room.

4. Suspended ceiling, forming an attic.

The air compartment itself is insulation, and at the same time, the attic can be ventilated separately.

5. Special power-free turbine ventilation ventilator and ridge ventilation ventilator for light steel structure metal roof, the one-time cost investment is high, however, almost zero energy consumption and maintenance cost during production and use, reasonable design and layout can ensure the good effect within the scope of the workshop, but it will loss the indoor heat.

6. The metal roof is made of two methods: single-laminated board with steel wire mesh underneath, glass wool with aluminum foil in the middle (hereinafter referred to as single), or double-layer steel sheet with glass wool (hereinafter referred to as double).

Pay attention to both methods:

(1).Use glass wool with single layer aluminum foil. When installing the entire roof, you must pay attention to ensure that it is continuous without omission or disconnection to eliminate cold bridges. Use aluminum foil tape to connect laps to ensure vapor tightness.

(2).Pay attention to the tension of the steel mesh when laying the steel mesh on the metal roof to ensure that it hangs properly between the adjacent purlins. Just in case, place an inverted nail plate directly above the production line to prevent condensation from entering the production line; The double metal roof must be noted that the indoor roof panels should be laid in the order from the ridge to the eaves, and the gutter design should consider the corresponding condensate drainage structure. For light steel structure workshops with a large amount of evaporation during production, preventing condensation is very important. Possibly causes: glass wool is saturated with condensed water and the roof load increases exponentially, condensed water drips into the production line and causes contamination of equipment and product , the deterioration of indoor environment, etc.