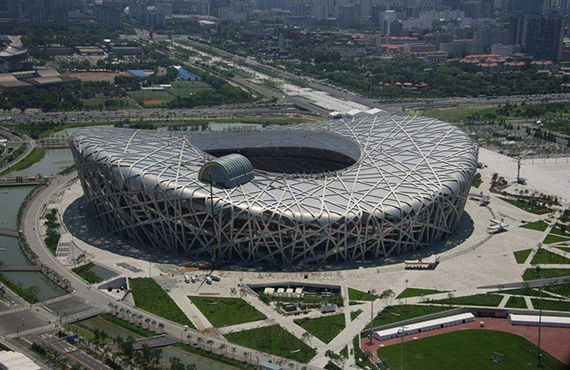

Bird's Nest of Chinese Steel Structure Engineering

- 18 Jan 2020

- steel structure

1. Basic situation of the project

Project location: Southeast side of Olympic Park, Chaoyang District, Beijing

Construction cost: 3.3 billion yuan

Building area: 258,000 m2

Building height: 69.2 meters

Structure type: reinforced concrete frame-shear structure and steel structure

Commencement date: December 24, 2003

Completion date: June 28, 2008

Project use: The main venue for the opening and closing ceremonies of the 29th Olympic Games in Beijing in 2008 and the main track and field venue. After the Olympic Games, it will be used for people to visit and sports venues for the public; after some transformations, it will improve the catering, commercial and cultural facilities for other operations Business.

2. Features, difficulties and technological innovations of the project

Highlight the construction concept of "Humanistic Beijing, Science and Technology Beijing, Green Beijing" and the overall requirements for energy conservation and environmental protection, and summarize the key points of filling in domestic gaps and gaining international advanced and international advanced technology.

2.1 Engineering Features:

The National Stadium is the main venue for the opening and closing ceremonies of the 2008 Beijing Olympic Games and the main venue for athletics. It consists of a main stadium, an outdoor warm-up field, an outdoor base, municipal administration, landscaping, hard landscaping, sports crafts, and opening and closing facilities. The building is in the shape of an elliptical saddle. The outer cover is a "bird's nest" -like heavy steel structure woven from twisted and twisted members. The interior of the three-layer bowl-shaped stands is a four-seven-story concrete frame shear wall structure. A standard track and field are set inside. And the runway and standard football field, which accommodates 91,000 spectators. The national stadium project has a large-scale construction, novel design, peculiar shapes, complex structure types, multiple cross operations, many professional subcontractors and suppliers, many inclined beams, inclined plates, inclined columns, and special-shaped structures. The durability is 100 years. The construction period is tight, and all sectors of society pay high attention and have a great impact.

2.2 Engineering Difficulties:

A. The engineering foundation has complex forces, high anti-floating water level, great pile foundation compressive resistance, level resistance, and pull-out resistance, and the soil is complicated. The determination of pile foundation design parameters is complex. Different types of caps have different depths, which guarantees the verticality of the pile, the accuracy of the pile position, and the difficulty of pouring the pile.

B. Due to the unique architectural effect of the "Bird's Nest", the space structure of the concrete bowl-shaped stand composed of irregular inclined beams, inclined columns, inclined plates, special-shaped members, large conversion beams, etc. is complex, and there is no standard floor and standard components. The outer edge is irregular, and it is difficult to erection the construction frame, especially the 21-meter-long inclined column and top space ring beam template design, selection, and on-site support methods. There is no precedent at home and abroad for the selection of concrete casting schemes. Very difficult.

C. The single-layer super-long and super-thick foundation slab without expansion joints has high requirements for crack resistance and durability indicators, and it is difficult to control the cracks on the ground structure.

D. The production, installation and installation of 25,000 kinds of prefabricated concrete stands for 15,000 pieces and 300 cast-in-place concrete concrete channels require accurate component dimensions, stable strength, smoothness, and uniform color, which place high requirements on formwork, concrete placement, and maintenance.

E. Due to the 310-kilometer all-welded connection process for steel structures, including different thicknesses from 110㎜ to 15㎜, the space-torsion members with a rectangular cross-section of 1200 × 1200 from Q460E to ordinary steel plates are assembled and welded in the air. Two winters and one summer are very difficult to control the quality of welding.

F. Deep design, component processing, on-site assembly, lifting docking, closing, support and unloading, and spatial welding of large-span steel structures composed of various types of space-bent and twisted steel members are very difficult.

G. The oblique beams, columns, and special-shaped concrete frames are intertwined with giant space steel trusses. The space is large, the components are irregular, and the spatial positioning and adjustment of construction errors are difficult. It places high requirements on measurement and control technology.

H. Steel structure and concrete structure are interspersed with each other. There is a large amount of deformation of 72 两种 between the two structures under the influence of temperature. It is difficult to waterproof the deformation joint.

I. Single-layer ETFE and PTFE membrane structure has a large area and is difficult to construct. The shape and size of each unit are different. It is not easy to cut and heat-seal. The shoulder of the steel structure is a cantilever structure. The shoulder membrane unit It is more difficult to install construction frames and safety measures.

J. Decoration and decoration, using pure hand-made, in three colors of red, black, and white, the large area of the outer wall is made of light steel keel and light partition wall. In the decoration process, there is no kick, no face, no pressure angle. The design of the three non-decorative nodes makes the construction quality control very difficult.

K. There are many electromechanical equipment systems, special functions, various types of pipelines and equipment crisscross, and new technologies, new processes, new equipment, and new materials. It requires careful planning and deployment, which can be completed through in-depth and detailed program demonstration and deepening design.

L. Due to the large number of four new technologies used in the engineering design, there are no standards for the construction of multiple subprojects, and there is no mature construction experience and technology to draw on.

M. The construction period of the project is tight. The actual construction period is only 4 years. The rehearsal of the opening and closing ceremonies and the two test competitions have greatly affected the construction progress.

N. Due to the high degree of social attention and the need for the opening and closing ceremonies, there are many modifications and changes to the engineering design, which further increases the difficulty of quality control of the overall project.

O. 8 sub-unit projects and 14 special acceptance projects. The site is narrow, there are many three-dimensional cross-operations, the construction period is tight, there are many professional categories, and there are many subcontracting units. Construction organization, coordination, technology, and quality control are difficult.

2.3 Scientific and technological content of the project

Based on the characteristics of the project, it carried out sci-tech information renewal and retrieval, initiated scientific research projects, and set up 14 research groups to be responsible for implementation. Completed 18 scientific research projects in the Ministry of Science and Technology and Beijing. It was included in the 5th batch of Ministry of Construction's new technology application demonstration project, and applied and promoted the Ministry of Construction's promotion of 50 new technologies among the ten major new technologies, and achieved good results. In March 2008, it passed the Ministry of Construction's science and technology demonstration project acceptance. In general, it has reached the international advanced level, including welding of high-strength steel and thick steel plates, and comprehensive installation technology of special-shaped and complex steel structures.

3. Analysis of the main economic and social benefits after the project is put into use

The project entered the operation team on March 20, 2008 and the opening and closing ceremonies entered the team. After April 18, it passed the test competition and the Good Luck Beijing Invitational. It ended successfully on September 17, 2008. It lasted five. In January, the project withstood a total of more than 10 million visitors and more than 1,200 units of various large-scale equipment to perform various operations of the foundation and foundation, structure, waterproofing, decoration, decoration, and mechanical and electrical equipment. Operation and test, no problems and repair items occurred during the continuous use time of up to 5 months, which ensured the smooth progress of various activities.

The National Stadium project carried the opening, closing ceremonies and all track and field events of the 29th Olympic Games and the 13th Paralympic Games in the history of a high-level, distinctive, and exquisitely incomparable and unparalleled Olympic Games. Fifteen items broke the world record and were highly appraised and praised by audiences, athletes, officials, the media and the International Olympic Committee of all countries in the world. They successfully completed important key missions smoothly and satisfactorily. It has become a valuable world-renowned Olympic historical and cultural heritage and a landmark building in Beijing. It is a magnificent and magnificent pearl in the Beijing Olympic Park.