container house

- 20 Mar 2020

- container house

At present, a large number of temporary housing materials are basically divided into two types: container houses and sandwich panel prefab houses, each of which has advantages and disadvantages. This article will introduces the container house.

Container house: container assembly type, factory processing, fast on-site assembly, limited production, and higher price than sandwich panel prefab house. There are two commonly used container houses: one is a flat pack container house. At present, most domestic emergency hospitals use this type of container house, and the other is a dry cargo shipping container, which is a container used for goods transportation.

Living container house

Material introduction

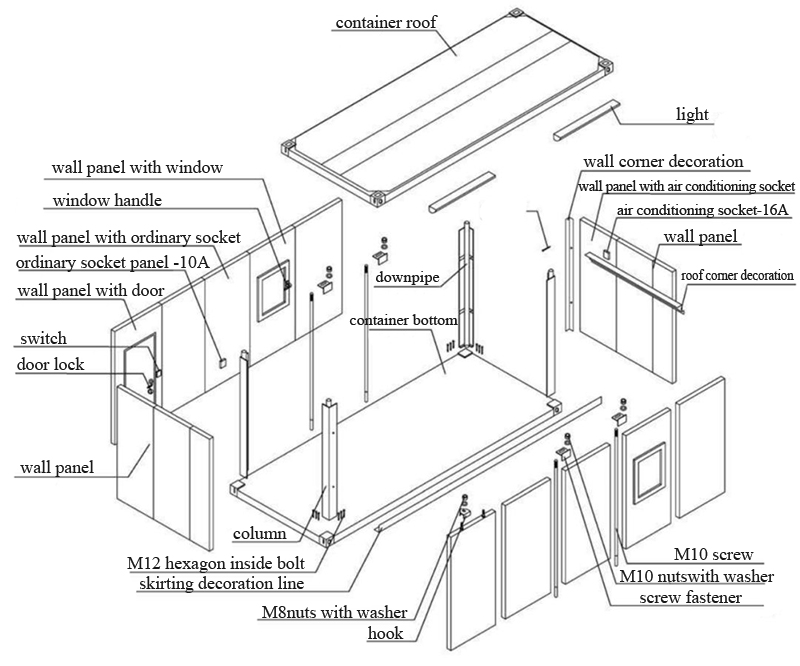

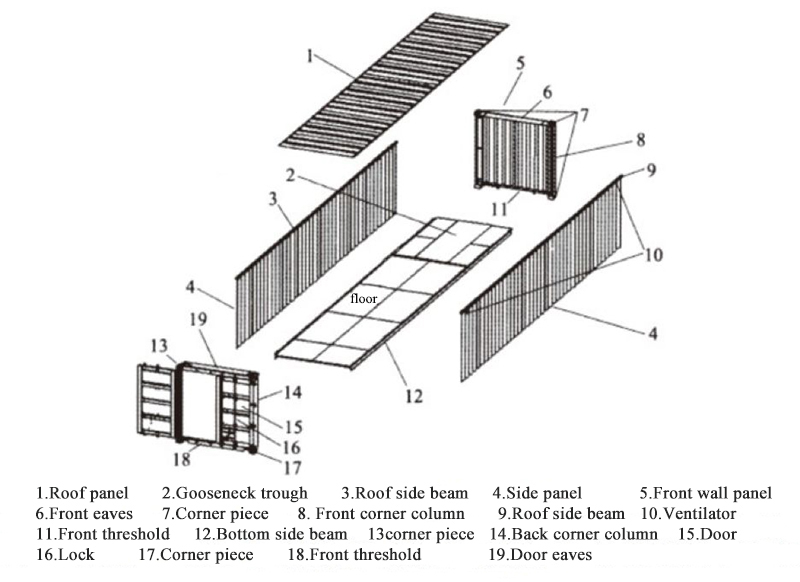

Composition materials: It consists of top frame components, bottom frame components, corner columns, and several interchangeable wall panels. Using modular design concepts and production technologies, a container room is modularized into standard parts and assembled on site or just hoist it down on construction site.

2. Advantages and disadvantages of material

2.1 Advantages: flat pack container houses use the container as the basic unit, the container structure is made of steel, and the maintenance and insulation materials are all made of non-combustible materials. The plumbing, electrical, decoration, and supporting functions are all prefabricated in the factory without secondary construction. It can be used alone, or it can be used to form a spacious use space or stack by different combinations of horizontal or vertical. The flat pack container house has a simple and safe structure and low requirements on the foundation. It has the characteristics of fast installation on site, convenient moving and relocation, many turnovers, long service life, etc., and there is no loss during disassembly, and no construction waste. The mineral wool insulation material filled in the structure itself and the frame structure itself can be recycled.

2.2 Disadvantages: It is necessary to follow the arrangement of unit modules, fixed modulus, and longer processing cycles for non-standard products.

3. Material properties

3.1 Technical parameters

| Technical specification | |||

|---|---|---|---|

| External dimensions | Assembly size 6058* 3000*2765mm | ||

| Package shipping size 6058*3000*2896mm | |||

| Internal dimensions | 5854*2796*2503mm | ||

| Self weight | 2300kgs | ||

| Insulation layer | Rockwool | ||

| Frame | Steel | ||

| Outer panel | 0.4mm steel sheet | ||

| Inner panel | 0.4mm steel sheet, 9mm Particle board | ||

| Floor | 15mm steel MGO panel 1.5mm PVC floor leather | ||

| Door | A steel door 755* 1985mm | ||

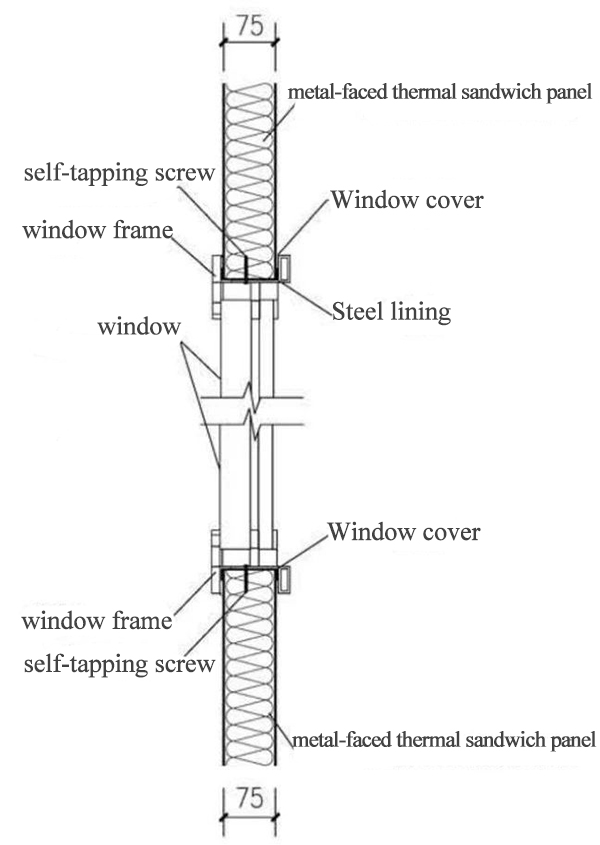

| window | 2 sets sliding window 900*1200 | ||

| Electrical standards | 3C 2lights(36W) 2socket 1 switch | ||

| Bottom bearing | 200kg/m2 | ||

| now load on top | 150kg/m2 | ||

| Bottom roof bearing | 150kg/m2 | ||

| Snow load on top panel | 100kg/m2 | ||

| Seismic performance | Three-story housing container module structure meets seismic fortification intensity of 7 degrees | ||

| Insulation performance | Thermal conductivity of roof | K=0.54(W/m2℃)90mm rockwool insulation layer | Note: Theoretical calculation |

| Thermal conductivity of bottom | K=4.15(W/m2℃)no layer | ||

| Thermal conductivity of wall panel | K=0.99(W/m2℃) 70mm rockwool insulation layer | ||

| Thermal conductivity of window | K=2.14(W/m2℃) | ||

| Thermal conductivity of door | K =1.22(W/m2℃) | ||

| Thermal conductivity of single container | K=1.49(W/m2℃) | ||

| Fire-proof level | Rockwool insulation layer | GB8246 A Non-combustible material | |

| Rockwool sandwich panel | fire resistance 0.5h GB/T9978-2008 | ||

| Environmental performance | Formaldehyde content=0.09≤10mg/m3 | GB/T18883-2002 | |

| Benzene=0.1≤0.11mg/m3 | |||

| TVOC=0.58≤0.06MG/M3 | |||

| Soundproof | Noise reduction26dB | ||

3.2 Durability: Design life is not less than 10 years.

3.3 Standard panel size: wall panel specifications 75mm × 1170mm × 2548mm

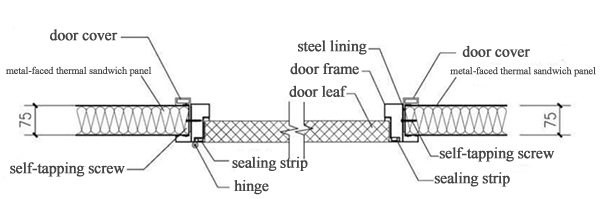

3.4 size: standard door 850mm × 2035mm son and mother door 1360mm × 2035mm (850mm large fan, 510mm small fan).

3.5 container type specification

| Item | Index | |||

|---|---|---|---|---|

| 6030 type | 6024 type | 6018 type | ||

| Outer size (mm) | length | 6055 | 6055 | 6010 |

| width | 3000 | 2435 | 1800 | |

| height | 2896 | 2896 | 2896 | |

4. Construction method

4.1 Basic Practice

4.2 Link Mode: Bolt

4.3 Electromechanical installation There are independent electromechanical pipes and water supply and drainage pipes in the container, and the pipes outside the container are connected to the box.

5. Decoration Practice

5.1 Waterproofing method: The bathroom floor and wall are made of high-temperature and high-pressure molded aviation resin material.

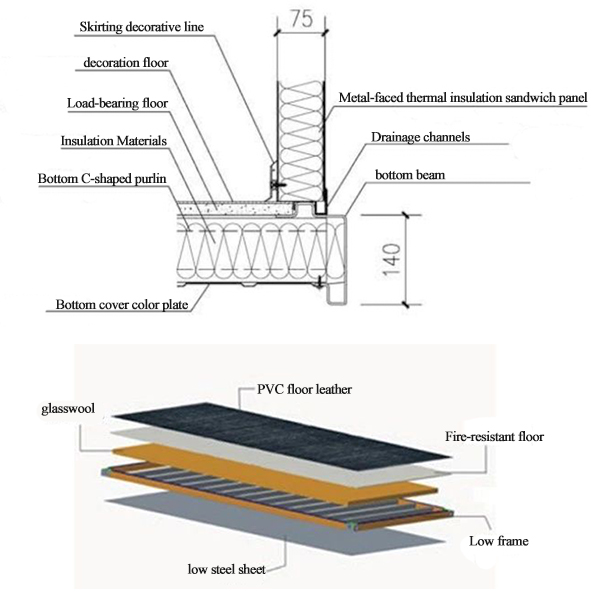

5.2 Ground Practic

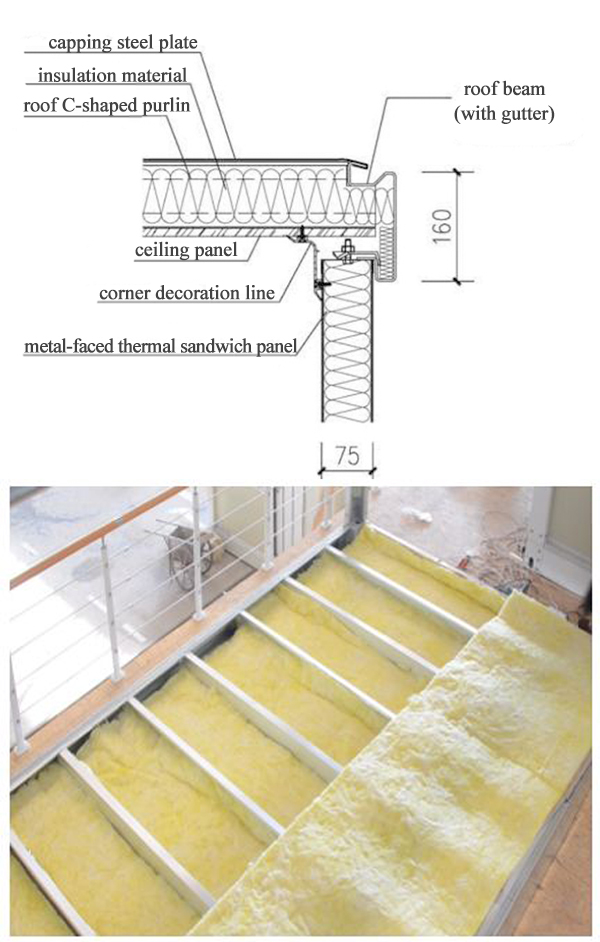

5.3 Roof Practice

5.4 Wall Practice

5.5 Doors and windows: Adopt one-piece door, which avoids cutting of the wall panel, and has better firmness and sealing performance.

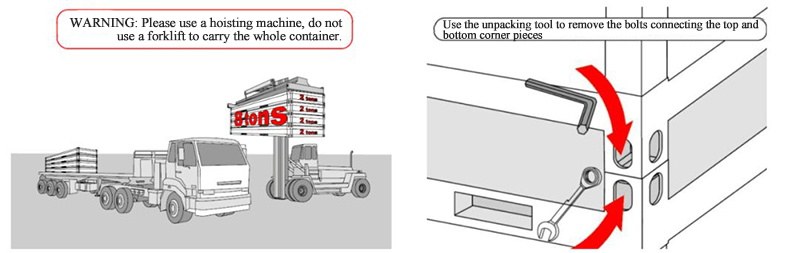

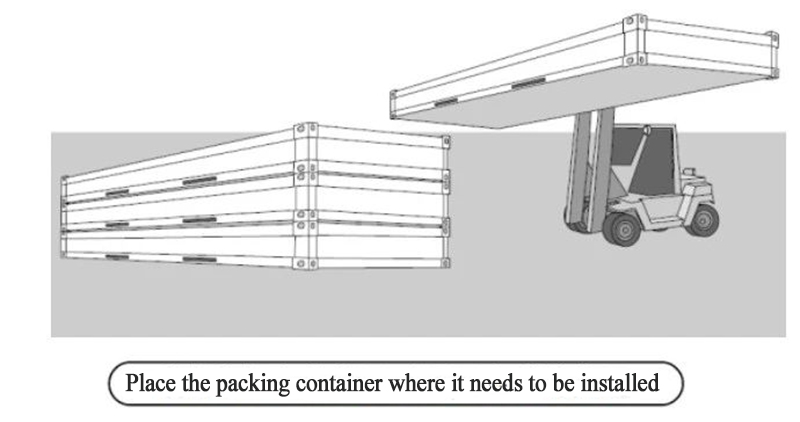

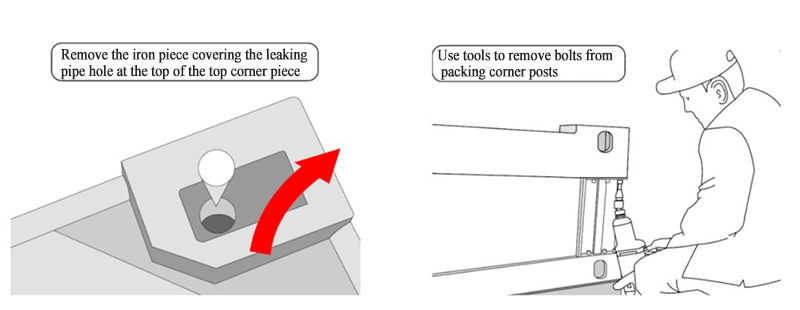

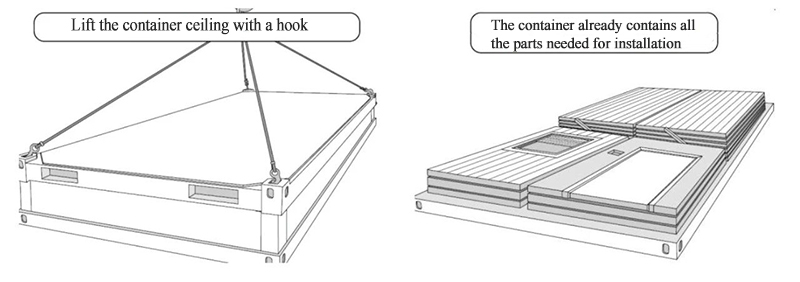

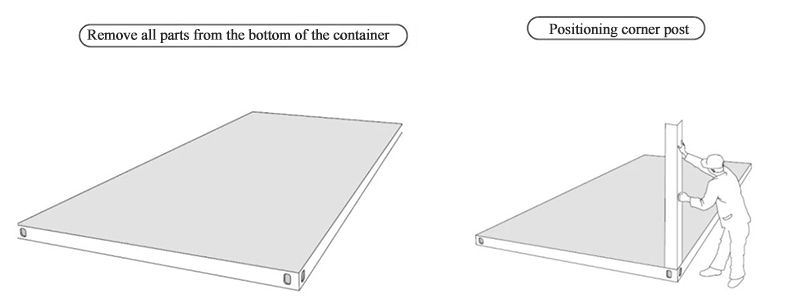

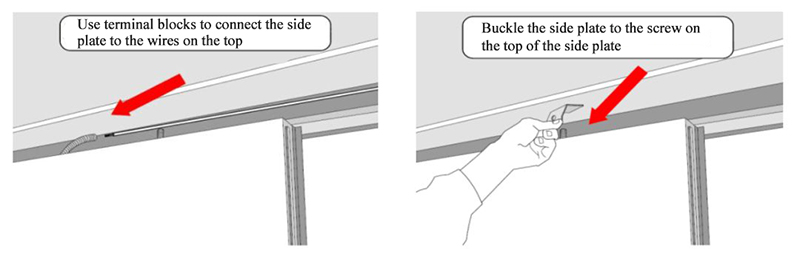

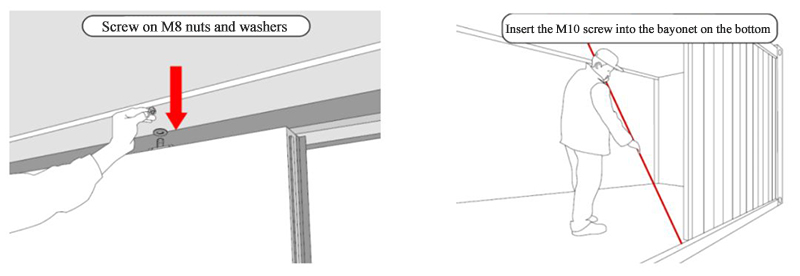

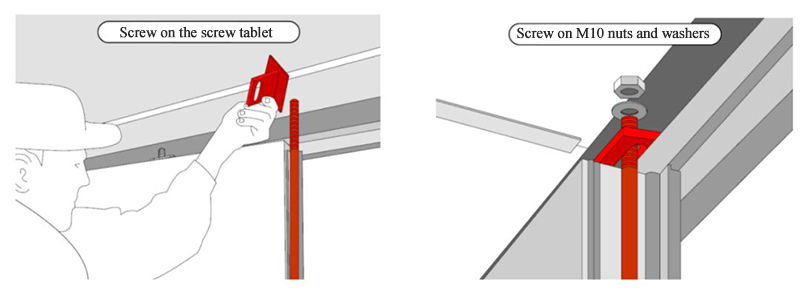

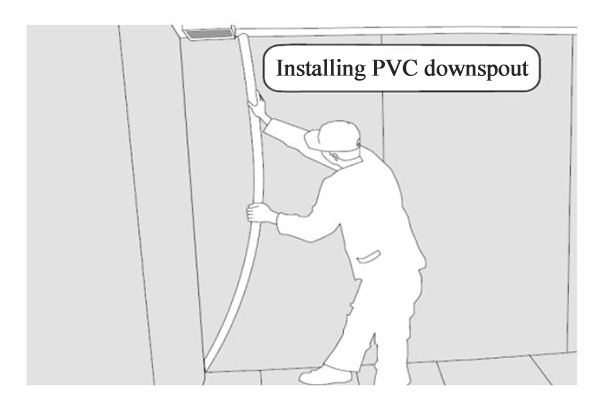

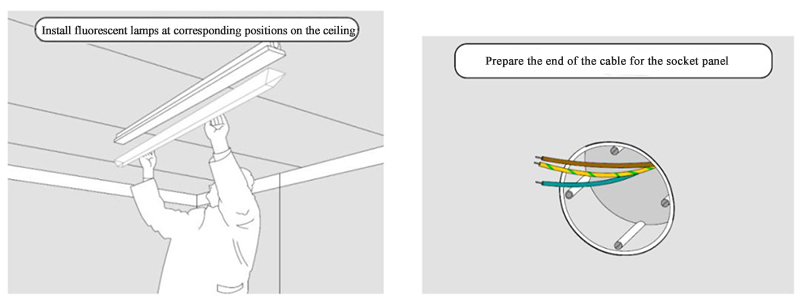

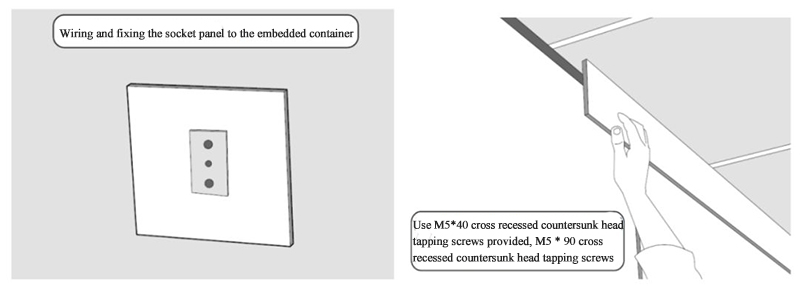

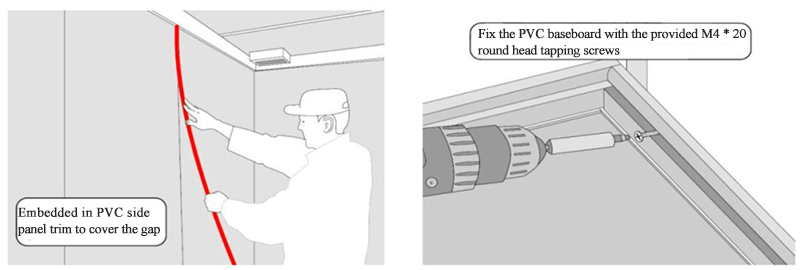

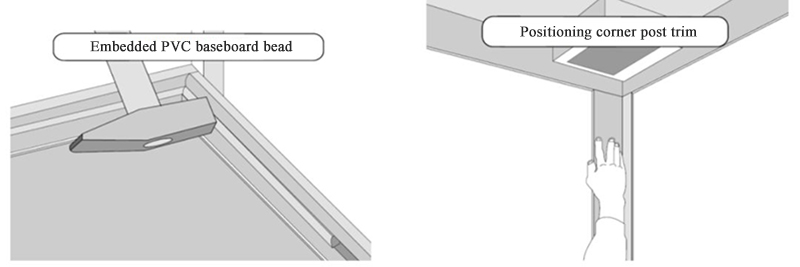

6. Installation steps

①

②

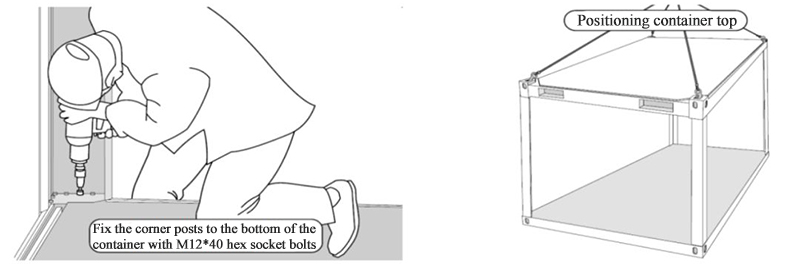

③

④

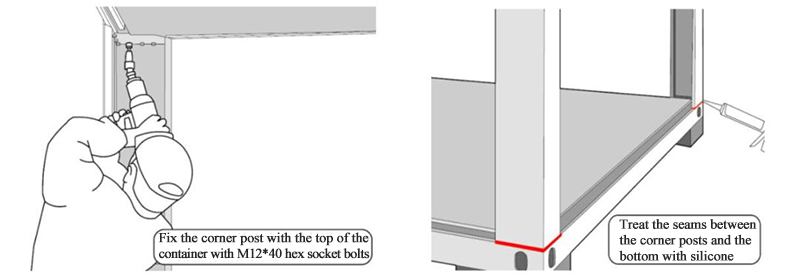

⑤

⑥

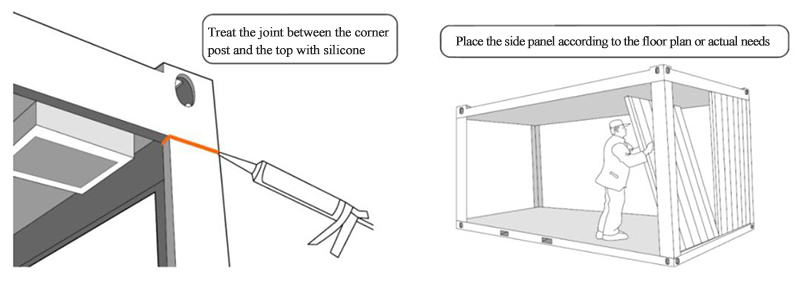

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

7. Installation speed

A single standard container, 2 skilled workers can complete the installation in 4 hours.

8. Material case

Dry cargo container house

1. Material introduction

Ordinary container, also known as dry cargo container. Mainly shipments of groceries. Dry cargo containers account for 80% of the total number of containers. The content covered in this article is a house composed of a finished product container with a building use function as a building unit module. Container mobile house, also called container house, container house, refers to a house with windows and doors that has been slightly modified, mainly based on finished containers.

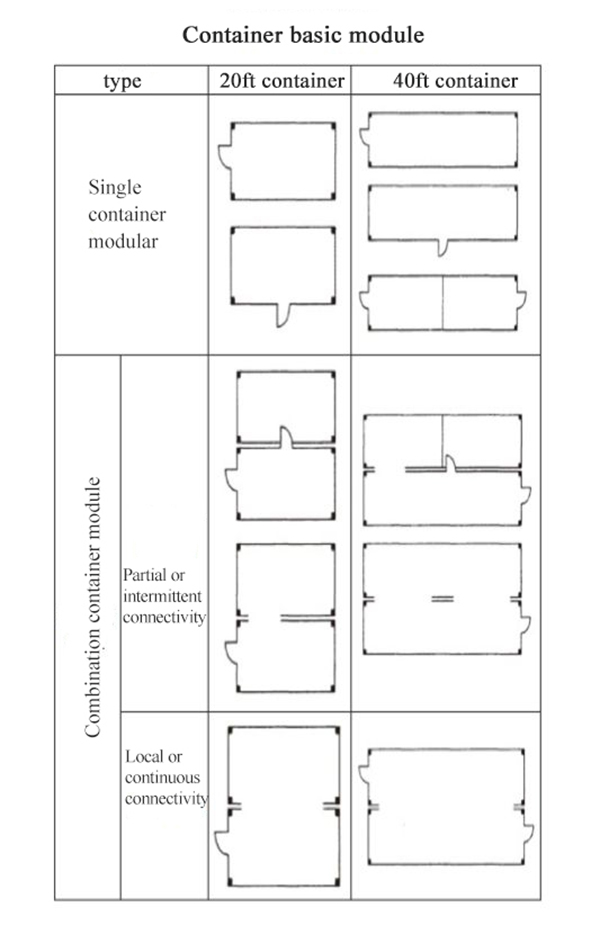

Component materials: The basic module of the container combination house is a single box module or a combination module, which has the following characteristics: the main functional space of the container combination house uses the basic module; the basic module with the same function should have universality and interchangeability. The completed interior decoration and equipment configuration adopt a standardized model. The components other than the basic module are also standardized or modular components, which are used together with the box module. The equipment uses centralized functional spaces, such as public toilets, showers, washrooms, laundry rooms, transformer rooms, pump rooms, kitchen operation rooms, elevator engine rooms, etc., mostly in container modules.

2. Material advantages and disadvantages

2.1 Advantages: Convenient transportation, especially suitable for units that frequently change the construction site. The container house is sturdy and durable, all made of steel, has strong earthquake resistance and deformation resistance, good sealing performance, and strict manufacturing process makes this kind of mobile house have Good water tightness. Easy disassembly, superior performance, stable and stable, good shock resistance, waterproof, fireproof and anticorrosive, light weight, the house is an integrated structure, with a frame inside, the wall is made of steel, can be decorated with wooden boards, can be migrated as a whole, and has a service life of 20 years the above.

2.2 Disadvantages: It is necessary to follow the layout of unit modules, fixed modulus, parts and components must be processed by the product factory, poor on-site installation flexibility, and longer processing cycles for non-standard products. The mineral wool insulation material that is not filled inside the structure itself has poor thermal insulation performance compared to packaged containers. If it is to be transformed into a house, this part needs to be treated separately.

3. Material properties

3.1 Durability: 10 to 20 years.

3.2 Standard size: As a container, it must first meet the requirements for convenient sea transportation. The width of the container cannot exceed 3m. It is divided into two models of 20-foot and 40-foot cabinets. Container mobile houses can splice containers according to demand.

3.2 Standard size: As a container, it must first meet the requirements for convenient sea transportation. The width of the container cannot exceed 3m. It is divided into two models of 20-foot and 40-foot cabinets. Container mobile houses can splice containers according to demand.

Main dimensions and rated quality of general-purpose container

| container type | outer size | min inner size | Rated quality(kg) | |||||||

| height(mm) | width(mm) | length(mm) | height(mm) | width(mm) | length(mm) | |||||

| size | limit deviation | size | limit deviation | size | limit deviation | |||||

| IAA | 2591 | 0-5 | 2438 | 0-5 | 12192 | 0-10 | 2393 | 2352 | 12032 | 3640 |

| ICC | 2591 | 0-5 | 2438 | 0-5 | 6058 | 0-6 | 2393 | 2352 | 2598 | 2180 |

4. Construction method

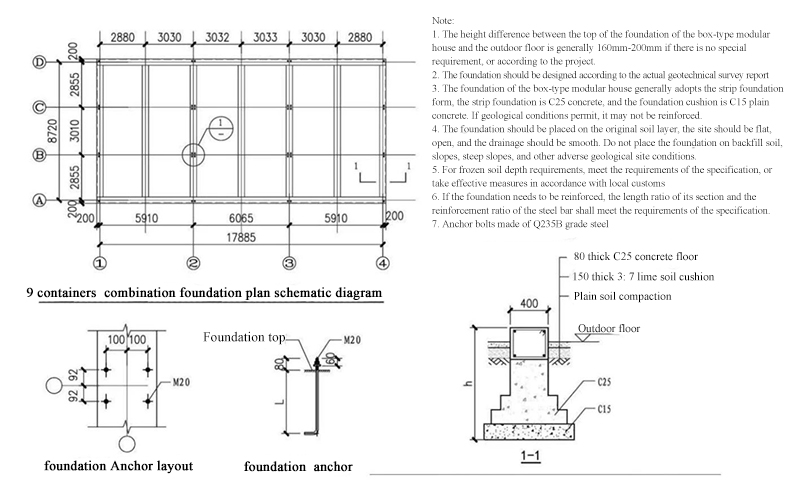

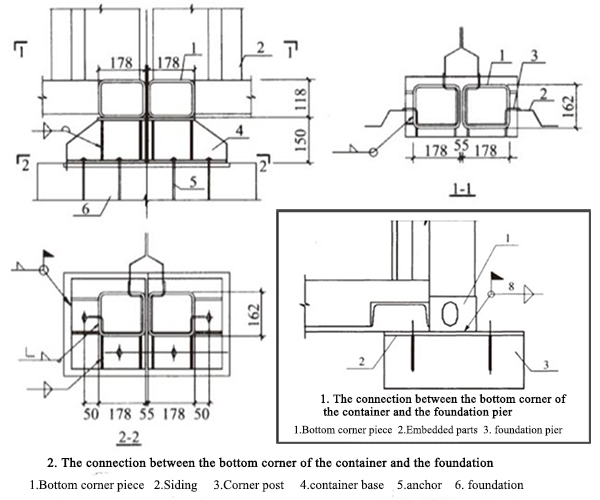

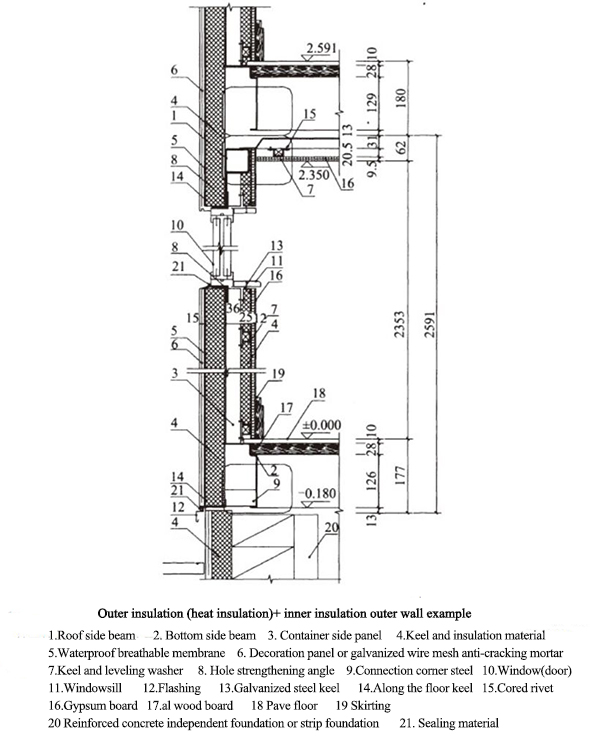

4.1 Basic practice: Natural foundations should be used for container composite houses. When the bearing capacity of the foundation soil of the low-rise building structure is less than 60kPa or the bearing capacity of the foundation soil of the multi-storey building structure is less than 100kPa, and when the foundation soil is a poor foundation such as soft soil, it should be carried out. Foundation treatment.

Expansion foundation should be adopted as the foundation form. Its buried depth should not be less than the freezing line depth or 0.5m, and the bottom surface should have plain concrete cushion. When the foundation soil of a single-layer container composite house meets the bearing capacity requirements and no surface water is trapped, the foundation soil of the container bottom can be tamped and leveled, and the box body is supported by a plain concrete pier (Figure 1). When the load of multiple boxes is large, the four corners of the box bottom can be connected to the foundation by corner bases.

4.2 Link method: The connection nodes of the container composite house structure shall be reasonably constructed, the transmission force shall be reliable and convenient for construction; the calculation and construction of the nodes and connections shall comply with the provisions of the current national standards.

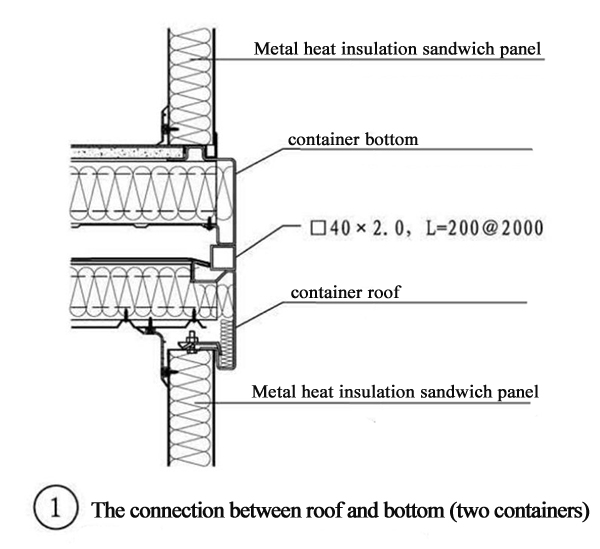

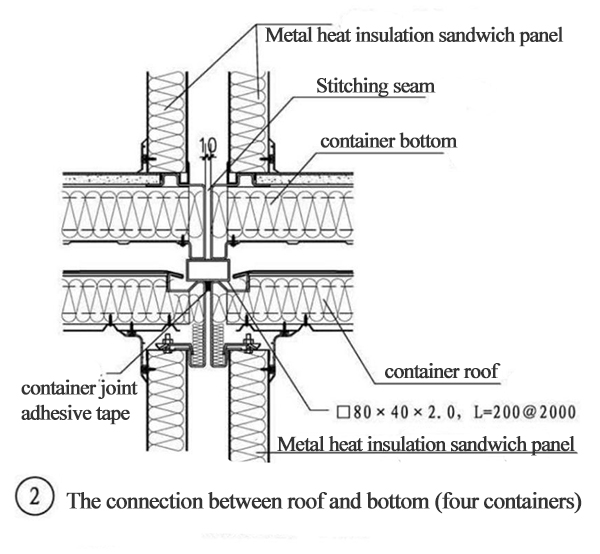

The connection between the containers should adopt the structure of connecting corners. The connection of the nodes should ensure reliable shear, compression and pull-out bearing capacity. The horizontal connection between the frame and the box should use the connector and the angle of the box. For the connection structure of joints, the joint connection should be a structure that only considers horizontal force transmission. The penetration welds of the connection of important components or nodes shall not be lower than the requirements of the secondary quality level; the quality of fillet welds shall meet the requirements of secondary welds of visual inspection. The on-site connection structure of the cabinet should have a working space for screwing and welding and easy installation and positioning measures.

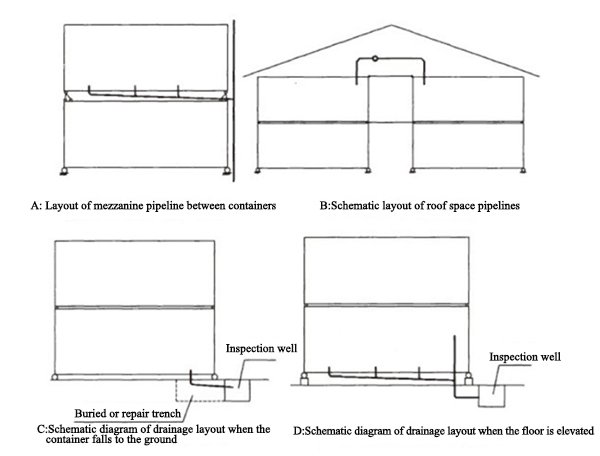

4.3 Electromechanical installation: The vertical and horizontal equipment dry pipes of multi-layer container combination houses should be located in the indoor space or outer porch outside the box (except for plumbing pipes in cold and severe areas) to avoid or reduce the continuous pipe running through the box. The vertical main pipe should be provided with a pipe well or at a suitable location.

When the container combination house is heightened with vertical spacers or provided with a roof mezzanine, horizontal equipment pipelines can be set in the mezzanine (as shown above), and its clearance should meet the requirements for installation and maintenance operations. When the outside diameter of the equipment pipeline is not greater than 110mm, the position can be determined by the structure professional, and a hole can be passed through the web of the container chassis beam. Reinforcing measures should be taken if necessary. When weather conditions permit, water supply and drainage pipelines can be installed outdoors. The equipment pipeline in the prefabricated box module should be pre-installed, and the location and form of the interface with the external line should comply with the regulations for the design and connection operation of each professional system of the equipment.

5. Decoration Practice

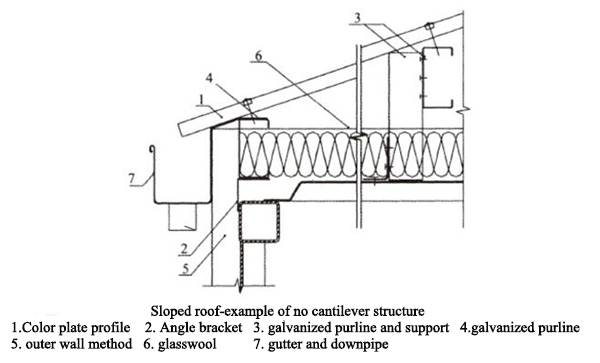

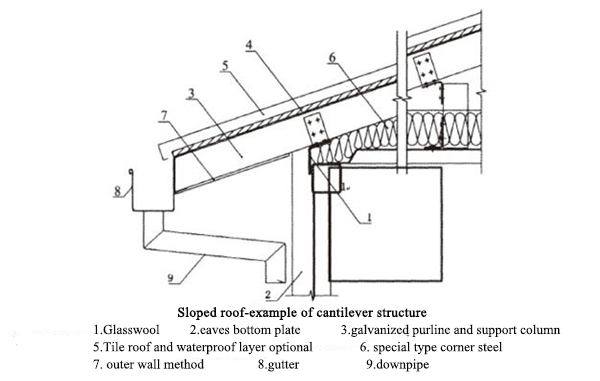

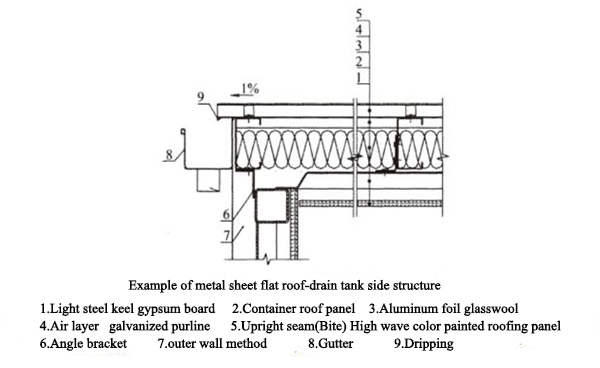

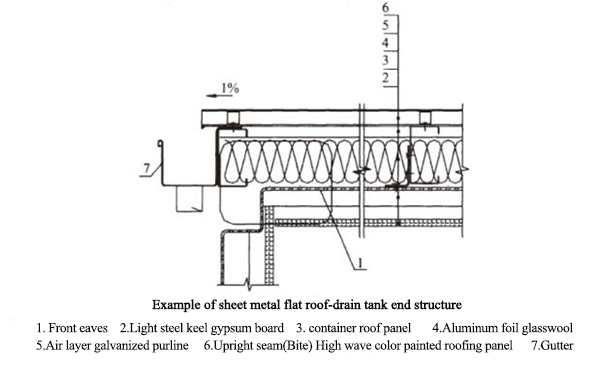

5.1 Roofing practice: The container roof should not be used directly as a load-bearing roof. It should be a light weight roof structure with a profiled steel sheet on the roof. Its requirements for waterproofing, sound insulation, and wind resistance should comply with the relevant national standards. The profiled steel sheet should be an undercut color-coated profiled steel sheet. Its performance and material should meet the requirements of the current national standards. The connection of the profiled steel sheet should be a concealed connection. Where the negative wind pressure on the roof is large, its connection should Strengthening measures; the slope of the slope roof should be greater than 5%; when the overflow gutter is made of color-coated steel, it should be firmly connected, and its thickness should not be less than 0.8mm; The calculation of load-bearing conditions determines that the rust-removing coating on the surface should be strengthened in accordance with outdoor conditions.

The purlins should be galvanized cold-formed steel and firmly fixed to the box.

5.2 Indoor Practice: The small bathrooms in the container combination house should adopt the overall bathroom, and the layout should meet the following requirements:

The overall bathroom should preferentially adopt the side drainage scheme. When the side drainage scheme is adopted, a piping space that can be installed and repaired should be provided; when the overall sanitary ware adopts the lower drainage scheme, the lower box top plate should be provided with maintenance manholes. When the whole bathroom adopts the scheme without external windows, ventilation devices should be provided; when the scheme with external windows is adopted, ventilation devices should be installed.

Non-integral bathrooms should be provided with a ground waterproof layer, and a flexible waterproof layer should be used. The bathroom waterproof floor with shower should be extended to a height of 1.8m on the wall. Continuously welded metal plate floor and wall can be used as waterproof layer.

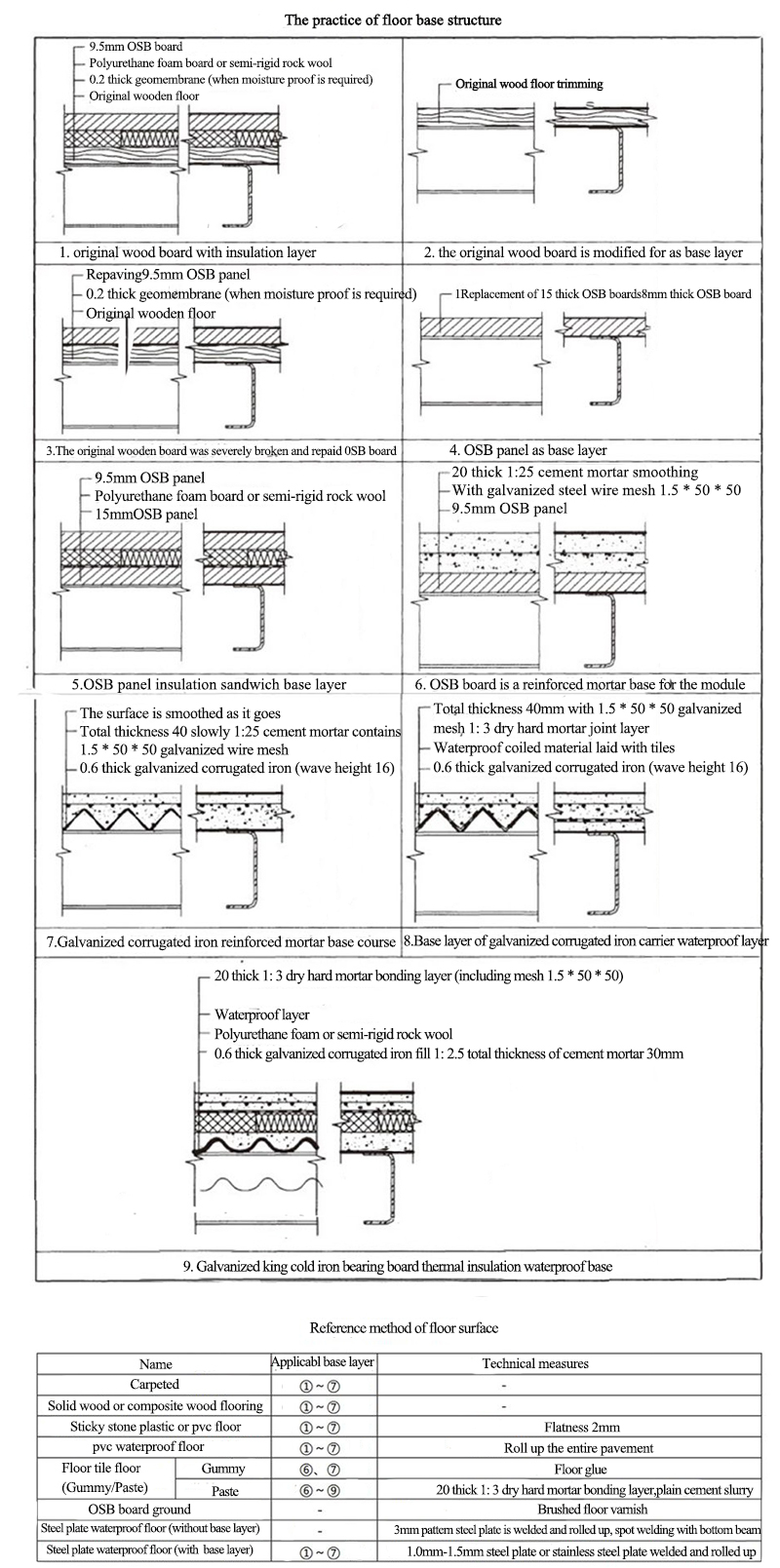

5.3 Ground Practice: When the original floor of an existing container is repaired and available, it should be used as the base of the floor (floor). When the structural connection at the corner of the container needs to be operated indoors, or when there is a requirement for pipeline connection operation, the floor (floor) board shall be provided with a movable cover plate or partially left on site to complete.

5.4 Wall Practice

6. Installation steps

Line laying-trench digging-concrete foundation beam and ground concrete cushion construction-container installation-walkway system installation-exterior wall panel installation-window installation-door installation-canopy system installation- Roofing system installation-cleaning site-completion acceptance.

7. Installation speed

A single standard container requires 2 skilled workers to operate, and complete installation can be completed in 4 hours.

8. Case Materials