Design of Rainwater Drainage System for Steel Structure Workshop

- 27 Aug 2019

- steel structure

According to the characteristics of roof form and roof structure of large area steel structure factory building, this paper puts forward various forms of rainwater drainage system of large area steel structure factory building, and discusses the characteristics and suitability condition and technical requirements of each rainwater drainage system according to the actual situation of building and roof, structure form of gutter, climate condition and production process requirements.Finally, some problems that should be paid attention to in the design of rainwater drainage system for steel structure workshop are put forward.

Summary

The roof and gutter structures of steel structure workshop are different from those of reinforced concrete workshop. The former mostly uses steel structure roof, purlin and steel beam; the latter mostly uses prefabricated reinforced concrete large roof slab and broken line roof truss or large steel structure roof truss. Although the roof and gutter of the steel structure workshop have roof eaves at the joint, there are still overlap joints. The roof and gutter are generally covered by no waterproof membrane, while the roof waterproof membrane of the reinforced concrete workshop covers the whole trench. Therefore, when the water level in the gutter of the steel structure workshop exceeds the overlap joint, rainwater will flood into the room from the lap joint.

Because of the limitation of purlin height on roof, the gutter depth of steel structure factory building is generally about 200 mm, and the effective depth is only about 150 mm, so the gutter is very shallow.In addition, the roof slope of the steel structure factory building is very large, and the rainwater coming down along the roof jet flows to the trench to produce impact surge, which causes the water level fluctuation in the trench to be very large, so the actual effective depth of the gutter is shallower.Therefore, the waterproof ability of roof and gutter of steel structure factory building is very weak. Once the drainage of rainwater system is not smooth or the rainfall exceeds the recurrence period, it is very easy to emit water.

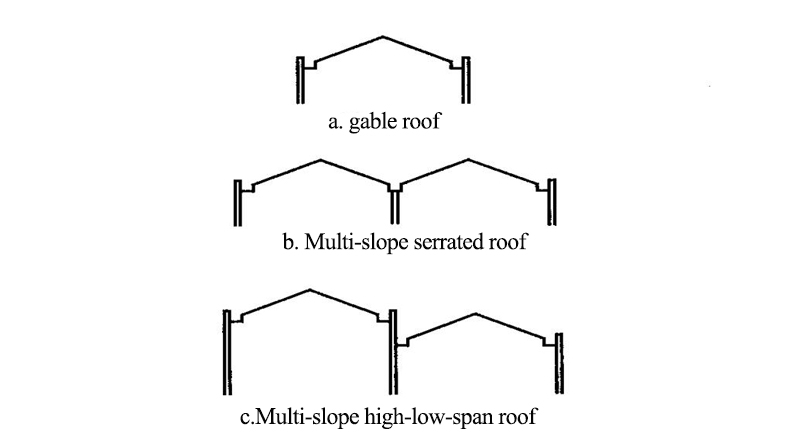

There are many differences in roof form and structure between steel structure workshop and civil building. The roof slope of large area steel structure workshop is large. If it is multi-span workshop, the middle span is often equipped with inner gutter. The shape of roof includes double-slope roof, multi-slope zigzag roof, multi-slope high and low span roof, etc. Fig. 1 shows several roof forms.

Figure 1 The roof form of steel structure factory building

Except for the improper calculation of rainwater system, a large part of the flooding and rising water of industrial plant floor and roof is due to the improper selection of rainwater system, while the design of rainwater drainage system of steel plant has many differences compared with civil buildings.

The roof rainwater drainage system of steel plant can be divided into two kinds: external drainage system and internal drainage system. The outdoor drainage system uses roof gutter to drain rainwater directly through outdoor riser to outdoor rainwater pipeline or open drainage channel, while the internal drainage system uses indoor rainwater pipeline to drain rainwater into outdoor rainwater pipeline.

The double sloping roof and other forms of roof side-span trench of steel structure workshop, that is, the trench adjacent to the outer wall, can be directly discharged by closed system to remove rainwater. The drainage effect is very good. As long as the calculation is reasonable, the phenomenon of water bursting will not generally occur. There are many choices for rainwater drainage system in Inner gutter of multi-slope zigzag roof and multi-slope high-low-span roof, such as long gutter drainage, gravity flow suspension pipe, open system buried pipe, closed system buried pipe, pressure flow (siphon) roof rainwater drainage, etc. The selection of various rainwater drainage systems should be based on the structure of buildings and roofs, gutters, climatic conditions and production process requirements, etc. after technical and economic comparison. If the rainwater drainage system is not properly selected, it will easily cause flooding, resulting in significant losses. The above-mentioned rainwater drainage systems have their own characteristics, applicable conditions and technical requirements, which are described below.

1.Classification of rainwater drainage systems

1.1 Long Gutter Outer Drainage Rainwater System

Long gutter outer drainage rainwater system has the features of no indoor rainwater pipe, no indoor leakage, low cost and convenient design. In the past, many kinds of drainage methods were used in reinforced concrete multi-slope zigzag roof and multi-slope high-low-span roof inner gutter.The "Code for Design of Building Water Supply and Drainage" (GB50015-2003) stipulates that the gradient of #steelgutter should not be less than 0.003, but the "Code for Acceptance and Acceptance of Roofing Engineering Quality" (GB 50207-2002) and "Code for Design of Machinery #FactoryArchitecture" (JBJ 7-96) stipulate that the longitudinal gradient of gutter and gutter should not be less than 1%, and the water drop at the bottom of gutter should not exceed 200 mm. According to the above stipulations, the distance between rainwater buckets should not be greater than 40 mm, so the drainage from the long trench can not be used for factories with a length of more than 40 m, but now the length of factories is generally more than 40 m.

For the #steelstructureworkshop whose length does not exceed 40m, because the gradient of the trench is not less than 0.01, the thickness of looking for the slope at the dividing line of the trench will reach 200 mm. The depth of the gutter of the #steelstructureworkshop will be limited by the purlin height. The depth of the gutter is generally less than 200 mm, and the thickness of looking for the slope can not reach 200 mm. Therefore, the #steelstructure workshop should not use the long gutter drainage.

In addition, the drainage and rainwater system of long gutter is only equipped with rainwater buckets at the end of the ditch. The number of rainwater buckets is very small, and they are easily blocked by ice and snow in cold areas. Due to the aesthetic requirements of modern factory buildings, generally the trench does not extend outside the parapet wall, and there is a crack between the light steel roof and the parapet wall. It is difficult to deal with the overflow opening in the building. Therefore, even if the length of the factory building does not exceed 40m, it is not appropriate to use the long trench drainage mode.

1.2 Gravity Flow Suspension Pipe Rainwater System

The gravity flow suspension pipe rainwater system belongs to the internal drainage system, which connects the middle span rainwater with suspension pipe to the outside wall and drains downward to the outdoor rainwater pipe drainage system.

If gravity flow suspension pipe is used to remove rainwater in the middle span of large-span and multi-span workshop, the structure form of workshop, roof and roof truss, production process requirements, etc. must be understood in detail. On the basis of careful analysis, whether suspension pipe can be used and how to arrange suspension pipe should be determined.

The gravity flow suspension pipe rainwater system belongs to the internal drainage system, which connects the middle span rainwater with suspension pipe to the outside wall and drains downward to the outdoor rainwater pipe drainage system.

If gravity flow suspension pipe is used to remove rainwater in the middle span of large-span and multi-span workshop, the structure form of workshop, roof and roof truss, production process requirements, etc. must be understood in detail. On the basis of careful analysis, whether suspension pipe can be used and how to arrange suspension pipe should be determined.

Suspension pipes are liable to vibration in factory buildings. Pipes should be sealed, tight and leak-proof. Steel pipes, PVC-U water supply plastic pipes, ABS water supply plastic pipes or orifice steel-plastic pipes are generally used. Suspension pipes should not be placed over production equipment, products and raw materials that may cause harm in case of condensation or leakage. The suspension pipe system is also not suitable for use in clean workshops.

For steel structure workshop, it is not appropriate to use gravity flow suspension pipe overhead method to remove rainwater in the middle span. Under the roof of steel structure factory building is steel beam with the same slope as the roof, without roof truss. If the suspension pipe is arranged along the horizontal direction of the factory building, because the distance between the suspension pipe and the roof is large (the roof is the largest) and the diameter of the suspension pipe is large, it will affect the beauty of the factory building. If the suspension pipe is arranged along the longitudinal direction of the factory building, there are many problems. Because the steel structure factory building pillars are small, the column spacing is generally more than 6 meters, and the diameter of the suspension pipe is often larger. On the one hand, it affects the beauty of the factory building. On the other hand, the suspension pipe should be hanged between the two pillars besides the support at each pillar. If there is no crane beam, it is very difficult to force on the roof. Generally, steel beams are supported by trusses or pipelines between columns, and pipes are fixed on trusses or pipeline support steel beams. This method is complex and has an impact on beauty. Therefore, it is not appropriate to use gravity flow suspension pipe overhead method to remove rainwater in the middle span of large-span and multi-span workshop of steel structure.

1.3 Underground Rainwater Pipeline System in Open System

The buried rainwater pipe system in the open system, i. e. the buried rainwater pipe and inspection well in the workshop, is widely used in the rainwater drainage in the middle span of the steel structure workshop. The system does not have the problems mentioned in section 1.2 of this paper, but there is the possibility of water outburst in indoor rainwater inspection wells.

In order to avoid rainwater coming out of indoor inspection wells, it is suggested that the rainwater amount be calculated according to the intensity of 5 rain rainstorm in the recurrence period of 5 a < P < 10 a, and the buried rainwater pipe be calculated according to gravity flow.

In the open system, the buried pipe rainwater system, the high-speed aerated water flow in the rainwater riser separates the gas and water in the inspection well, and the energy conversion produces positive pressure splash. In order to eliminate the gas flow in the pipe and stabilize the flow, outdoor gas wells should be installed in the discharge pipe of the open system. Because of the shallowness of the inspection well at the beginning of the buried pipe, it is susceptible to water bursting due to the influence of air flow. Therefore, it is suggested that an extended roof ventilation pipe should be installed in the inspection well at the beginning of the buried pipe to extend the roof along the column. The starting inspection well shall not be connected to the production wastewater drainage pipe.

The design of buried pipe rainwater system in open system should also consider improving the flow state of rainwater from riser to buried pipe as far as possible. Otherwise, inappropriate connection of pipeline will aggravate the disorder of water flow in inspection wells, which will make the water flow in wells not smooth, water level rising or gas-water boiling, and cause the possibility of water outburst. There are several effective measures to improve the water flow state as follows: First, the outlet of the rainwater drainage pipe connected to the indoor inspection well should be connected with the downstream buried drainage pipe flat, so as to reduce the water flow drop and improve the water flow condition from the elevation. (2) The water flow angle should not be less than 135 at the time of access. In order to improve the flow conditions in the plane. (3) Inspection wells with high flow grooves and diversion grooves 200 mm above the top of the pipe, and inspection wells with depths of not less than 700 mm in order to improve the flow state and avoid water flooding.

By adopting the above measures to exhaust and improve the flow state, the problem of water outburst in the buried pipe rainwater system in the open system can be greatly reduced. However, the buried rainwater system in the open system is likely to emit water from the ground after all. Therefore, the system should not be used in clean and waterproof plants.

1.4 Buried Rainwater Pipeline System in Closed System

To fundamentally solve the problem of indoor water outburst in rainwater internal drainage system, for steel structure workshop with multi-span workshop, the inner drainage system can be used to remove rainwater, i.e. the indoor closed buried pipe and reinforced concrete indoor rainwater inspection wells. The buried pipes of the closed system should be sealed, tight and leak-free. The pipes of the rainwater system should adopt pressure-bearing pipes, such as PVC-U water supply plastic pipes, steel pipes, ABS water supply plastic pipes, water supply cast iron pipes, etc. The fabrication method of the inspecting opening of buried horizontal pipe is as follows: three-way openings on the horizontal pipe with flange cover plugging and rubber gasket sealing. In order to eliminate the air flow in the pipe and increase the drainage capacity, the discharge pipe should be equipped with outdoor gas wells, and indoor roof extension ventilation pipe should be set up along the column to extend the roof ventilation. In design, attention should also be paid to the location of sealed buried pipes and inspection wells so as to avoid setting up equipment bases. Inspection wells should be set up at the intersection of buried pipes in closed system or at the places where the length of buried pipes exceeds 30 m and where the risers are connected. Buried rainwater pipes should be designed according to full flow.

The buried pipe rainwater system in the closed system has no openings and will not cause floods. The pipeline is pressure drainage and has a large drainage capacity. However, due to the high cost of the system, the construction is complicated and the maintenance is inconvenient, and the influence of habitual factors, it is seldom used. However, the system has been used in many projects to remove rainwater. After many rainstorms, the effect is very good.

1.5 Pressure Flow (Siphon) Roof Rainwater Drainage System

All of the above mentioned systems are traditional gravity flow rainwater drainage system, which is the roof rainwater drainage mode that has been used in the design. The gravity flow rainwater bucket is used in the system. The traditional gravity flow rainwater drainage system often has many drainage pipes, large diameter, many inspection wells and small drainage capacity, which is more prominent for roof rainwater drainage system of large steel structure factory buildings.

Pressure flow (siphon) roof rainwater drainage system has been used for decades. This system has more advantages than gravity flow rainwater drainage system in large roofs and complex roofs. It can better meet building requirements and remove roof rainwater faster. However, the pressure flow (siphon) rainwater drainage system is limited because of its high cost, complex design and calculation, and the influence of habitual factors. However, with the development of the economy and the continuous improvement of the use requirements, the current use trend of the system is rising.

2. Some Problems in Design of Rainwater Drainage System for Steel Workshop

In addition to the problems mentioned in the middle part of the overview, the design of rainwater drainage system for steel structure factory buildings should also pay attention to the following issues.

The design of rainwater drainage system for steel structure workshop should be carefully considered and calculated accurately. Firstly, it is suggested to take a larger recurrence period, usually 10a.Gutter should have a slope of 1% according to the building regulations. Due to the limitation of the depth of gutter, the thickness of slope searching in gutter should not be too large. Therefore, the spacing of rainwater buckets in gutter should be within 12 M.According to this principle, after the rainwater bucket is laid out, the catchment area is divided, the drainage volume of the trench is determined, the cross-section area of the trench is calculated, the depth of the trench is the same as the purlin height, and the width of the trench is determined by calculation.In determining the width of the trench, besides satisfying the drainage, the influence of bracket installation under the trench by structural specialty should also be considered. The bracket is close to the bottom of the trench and is set along the longitudinal direction of the trench, which may affect the installation of the rainwater bucket and the rainwater pipeline under it. In consultation with the structural specialty, brackets at the bottom of the trench can be set on the side of the trench to ensure that the distance between the bracket side and the trench side meets the installation requirements of the rainwater bucket and the rainwater pipeline under it, or the width of the trench can be enlarged to eliminate the influence of the bracket. The roof of steel structure workshop is lapped by coloured steel plate, and the lap is fastened to purlin by screw or 360.In vertical hidden button connection, color steel plate generally has no waterproofing membrane and roof waterproofing capacity is weak.Each color steel plate consists of a wave crest and a trough, where the overlap is located at the wave crest and rainwater flows in the trough. Therefore, when the roof rainwater is too large, the rainwater may overflow the crest or even submerge the crest. At this time, the overlap may be completely submerged in the water, so that the rainwater enters the room from the overlap. For the steel structure workshop with high and low span roof, if the high span roof area is large, it can not drain the rainwater from the high span roof to the low span roof, so as to prevent the rainwater from flooding the overlap joints of the color steel plate and leaking water. Therefore, the large high-span roof should be separately provided with rainwater drainage system and directly discharged outdoors, but not directly discharged into low-span roof.

According to the Code for Design of Water Supply and Drainage in Buildings, overflow facilities should be set up for roof rainwater works of buildings, the total drainage capacity of gravity flow roof rainwater drainage works and overflow facilities of general buildings should not be less than the amount of rainwater in the recurrence period of 10 years, and the roof rainwater drainage systems of important public buildings and high-rise buildings should be water drainage works and overflow. The total drainage capacity of the facility should not be less than the rainwater amount in the recurrence period of 50 years. The design recurrence period of roof rainwater pipeline is 2-10 years, so the amount of rainwater that exceeds the design recurrence period of rainwater pipeline needs to spill over from overflow facilities. The installation of overflow facilities is particularly important for steel structure factory buildings. If there is no overflow facilities or overflow facilities are too small, the amount of rainwater beyond the design recurrence period of rainwater pipeline will accumulate in the gutter, which will make the water level in the gutter rise rapidly and submerge the overlap joint between roof panel and gutter, and the rainwater will flood into the room from the overlap joint. Steel structure trench can be set up at a certain distance outside the trench pipe overflow or square overflow, the building has standard drawings. When calculating the size of overflow outlet, the amount of rainwater that needs to be spilled from overflow facilities should be calculated first, and then the size of overflow outlet should be calculated according to Manning formula and submitted to construction specialty.

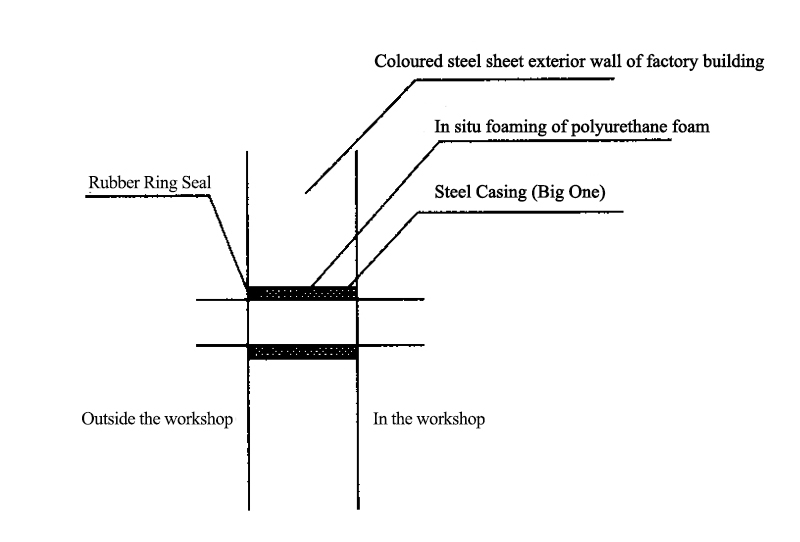

When installing rainwater pipes in steel structure factory buildings, try to avoid rainwater pipes passing through the outer wall to prevent rainwater from entering the room through the pipes. When it is necessary to penetrate the outer wall, sealing measures should be taken, as shown in Figure 2.

Figure 2 Pipeline Installation of Coloured Steel Plate Exterior Wall in Workshop

The gravity flow rainwater bucket has the function of rectifying, avoiding the formation of excessive vortices, stabilizing the water level in front of the bucket, reducing aeration and intercepting sundries such as leaves. Gravity-flow rainwater drainage system must be equipped with gravity-flow rainwater buckets, but in practical engineering, many construction units directly open holes in steel structure trench, and weld steel short pipes under the trench to connect with rainwater risers, without rainwater buckets. This method reduces the drainage capacity of rainwater system, and leaves and other sundries enter the rainwater pipe with rainwater. It is very easy to clog the rainwater pipe. In order to avoid this situation, first of all, the design drawings should clearly express the rainwater bucket, and at the end of the project to the construction unit to set up the requirements of rainwater bucket.

3.Peroration

With the development of economy, the requirement for the safety of roof rainwater drainage system design of steel structure factory building is higher and higher. The design of rainwater drainage system of large area steel structure factory building seems simple. There are many factors that need to be considered in practice, including structural form, climate condition, economic level, production process requirements, etc. Designers take it seriously, analyze it carefully and determine a reasonable plan. In addition, whether a rainwater drainage system design is successful or not often requires practical verification, we need to know more about the investigation and necessary design visits.