Design requirements of steel structure temporary prefab house

- 10 Apr 2020

- steel structure

1. General regulation

1.1 The design service life of the temporary construction house should be 5 years. The accumulated service life of container house components should not exceed 20 years.

1.2 The temporary building should be designed according to its use function, load, site conditions and other requirements. Structural components should be standardized in design to meet the requirements of easy dis-assembly and recycling.

1.3 The temporary building should adopt the limit state design method based on probability theory, and use the design expression of the partial coefficient for structural calculation.

1.4 The load-bearing structure shall be combined with the load (effect) according to the limit state of the bearing capacity and the limit state of normal use, and shall be designed with the most unfavorable load effect combination.

1.5 When designing according to the limit state of bearing capacity, the basic combination of load effects and the occasional combination of load effects should be considered. The design value of the load should be calculated as follows:

γ0S≤R

In the formula, γ0 is the coefficient of structural importance. The coefficient of structural importance of temporary buildings should not be less than 0.9. The coefficient of structural importance of office buildings and living rooms can be taken as 0.95. The coefficient of structural importance of light steel structures for special buildings can be determined separately according to specific circumstances.

S——The design value of the load effect combination at the limit state of the carrying capacity, and the S value shall be in accordance with the "Building Structure Load Code" GB50009, taking the most unfavorable load effect combination.

R——Design value of structural components resistance.

1.6 The standard value of wind load is 0.35kN / m2. The wind load carrier coefficient of temporary construction houses shall be implemented in accordance with the current national standard "Building Structure Load Code" GB50009.

1.7 The design shall consider the adverse influences of changes in the internal forces of the roof components due to wind suction. At this time, the load partial factor of the permanent load shall be 1.0.

1.8 The design shall consider the effect of the earthquake on the structure. The earthquake action and seismic measures of Class C buildings shall meet the fortification requirements of 7 degrees for seismic fortification intensity and 0.10g of design basic seismic acceleration value.

1.9 Thermal performance of the surrounding structure of the temporary building should meet the requirements of the following table:

Thermal performance of the surrounding structure of the temporary building

| Surrounding part | Heat transfer coefficient K[W/(m2·K)] |

|---|---|

| Roof | ≤0.55 |

| External wall | ≤0.6 |

| Floor | ≤0.6 |

| Window and door | ≤3.0 |

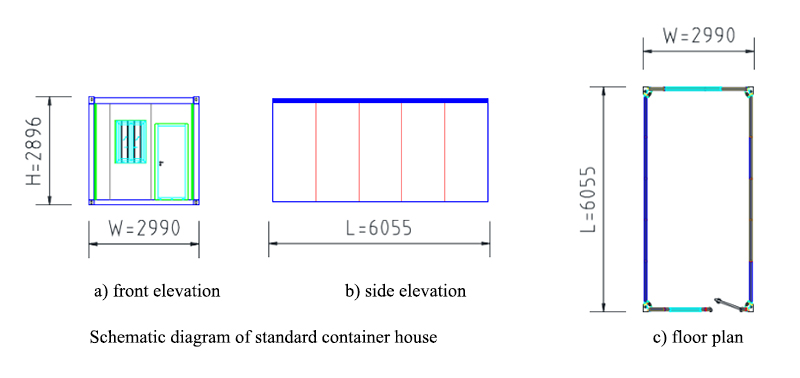

1.10 Container houses should be modular and standardized in design. Container body or structural components with the same use function should be universal and interchangeable. The external size (L×W×H) of standard container house should be 6055mm×2990mm×2896mm.

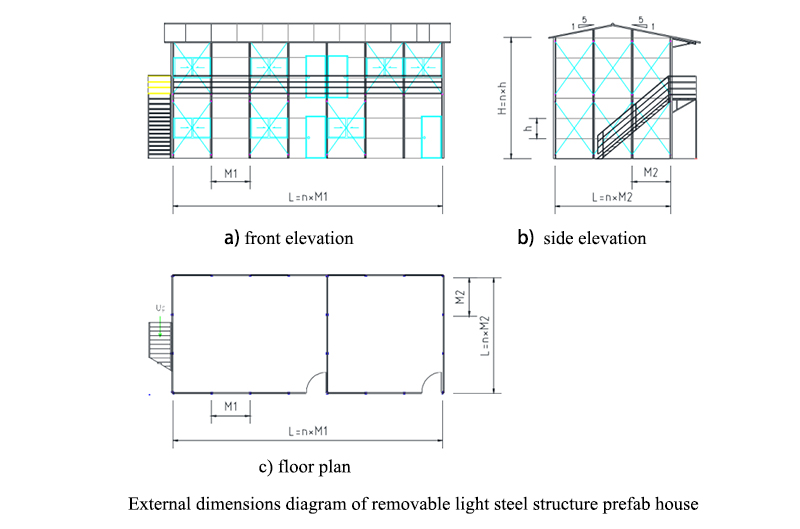

1.11 The removable light steel structure prefab house should adopt modular and standardized design . The combined size (L × W × H) should be calculated according to the following formula:

L×W×H=n1M1×n2M2×n3h (3.1.11)

In the formula:M1——Column axis distance in longitudinal direction, M1=1820mm;

M2——Column axis distance in depth direction,M2=1820mm;

h——single wall panel height,h= 950mm;

n1——Number of combinations in the longitudinal direction;

n2——Number of combinations in the depth direction;

n3——Number of combinations in the height direction;

The combined external dimensions of the assembled light steel structure prefab house are shown in the figure.

2. Building Design

2.1 The overall layout of the temporary construction house should be regular and balanced, and the appearance color should be simple and beautiful. The number of floors of temporary houses should not exceed 3, and the building area of each floor should not be greater than 300 m2.

2.2 The internal height of the handrails, the width of the stairs, the height of the steps, and the clearance height between the vertical bars of the railings of the office and dormitory rooms shall meet the relevant requirements of the current national standard "General Principles of Civil Building Design" GB50352. The height of outdoor stair railings handrail should not be less than 1.1m. The 0.1m height between railings and the floor should not be left empty.

2.3 The densely populated rooms such as conference rooms, dinning house, cultural and sports activities rooms should be set on the ground floor of temporary buildings, and their evacuation doors should be opened in the direction of evacuation. Office, dormitory, and warehouse rooms should not be constructed in combination with kitchen operation rooms, boiler rooms, and power distribution rooms. The recreation and sports room should be set up separately, and the use area should not be less than 50 ㎡.

2.4 The inside clear height of the office room should not be less than 2.5m, and the per capita area should not be less than 4 ㎡

2.5 The internal clear height of the dormitory room should not be less than 2.5m, the per capita use area should not be less than 2.5 ㎡, and the number of people in each dormitory should not exceed 15 people.

2.6 The storage for storing combustible materials and flammable and explosive dangerous goods should be one layer, the building area should not be greater than 200 ㎡, the building area of a single room in the combustible material warehouse should not exceed 30 ㎡, and the building area of a single room in the flammable and explosive dangerous goods warehouse should not exceed 20 ㎡. The explosion-proof and pressure-relief design of dangerous goods warehouses shall comply with the relevant regulations of GB50016 "Code for Fire Protection of Architectural Design".

2.7 The evacuation of temporary construction houses should meet the following requirements:

2.7.1 There should be no less than two safety exits for multi-storey temporary buildings and they should be scattered;

2.7.2 When the construction area of a single room in a temporary building exceeds 60 m2, there should be no less than 2 evacuation doors;

2.7.3 As for the linear distance from the evacuation door of the office and dormitory room to the nearest safety exit, if the evacuation door is located between the two safety exits,it should not be greater than 25 meters, but if the evacuation door is located on the sides or at the end of the bag-shaped walkway should not be greater than 15 meters;

2.7.4 The clear width of the evacuation door should not be less than 0.9m, and the clear width of the evacuation stairs and corridor should not be less than 1.1m.

2.8 The architectural design of the temporary construction house should meet the following requirements of energy saving and lighting:

2.8.1 Reasonably design the shape of the temporary building and reduce the shape factor;

2.8.2 The orientation of the house should be north-south;

2.8.3 Control the window-to-wall ratio, window-to-ground ratio, and window opening area of the external wall. Window-to- wall area ratio should not exceed 0.25,The window-to-ground area ratio of office and dormitory should not be less than 1/7, and the openable area of external windows should not be less than 30% of the whole window area;

2.8.4 The air-tightness of external windows of temporary buildings should not be lower than the current national standard Class 5 specified in GB/T7106 in Classification and testing method of air-tightness , water-tightness, wind pressure resistance performance of building external window and door;

2.8.5 The windows of temporary buildings should set up shading measures in summer.

2.9 The roof waterproofing of the temporary building shall meet the Grade II requirements of GB50345 in "Technical Specifications for Roof Engineering".

2.10 The design of the kitchen, bathroom, and garbage station of the temporary building shall meet the relevant requirements of JGJ146 in the Environmental and Sanitary Standards for Construction Sites.

3. Structural design

3.1 The temporary building should adopt load-bearing structural systems such as steel frames, steel trusses, portal steel frames, color plate structures with internal insulation, light steel structures, masonry structures, or container houses.

3.2 The structural system shall meet the following requirements:

3.2.1 Should adopt the geometrically invariant systems;

3.2.2 Should have clear calculation diagrams and reasonable power transmission channels;

3.2.3 Should avoid the loss of bearing capacity of the whole structure due to damage of partial structures or components.

3.2.4 Should reasonably control the size to avoid partial or overall instability of the component.

3.3 Joists or brackets should be arranged where the middle or side columns of the multi-span steel frame are partially removed.

3.4 The load effect combination should meet the following principles:

3.4.1 The evenly distributed live load on the roof is not considered simultaneously with the snow load, and the larger value of the two should be taken.

3.4.2 Concentrated loads during construction or maintenance shall not be considered simultaneously with other loads except the roof material or weight of the purlins.

3.4.3 Wind loads are not considered simultaneously with earthquake action.

3.4.4 The floor live load standard value of dormitory, office and other buildings should be taken as 2.0kN / m2. The floor live load standard value of the cantilevered corridor shall be taken as 2.5kN / m2 or be strengthened. When the use load is large or the situation is special, the value should be taken according to the actual situation.

3.4.5 The roof of the temporary building shall be considered as the roof without person on it.

3.5 For structural calculations of the components, such as steel frames, roof trusses, purlins and wall beams, the tensile and compressive strength should be calculated based on the effective net cross-sectional area, and the stability should be calculated based on the effective cross-sectional area. The deformation and various stability factors can be calculated according to the gross f cross-sectional area.

3.6 For connection calculation and strength calculation of steel structural members, please refer to the "Design Code for Steel Structures" GB50017 and "Technical Specification for Cold-Formed Thin-Walled Steel Structures" GB50018 and other specifications.

3.7 When calculating the internal forces of trusses and roof trusses of a temporary building, the secondary stress may not be calculated for nodes that are assumed to be hinged, but the adverse effects of internal force changes of roof truss members should be considered under the effect of roof wind suction and calculated Tensile bearing capacity of roof frame anchor bolt.

3.8 The components size should be reasonably divided in the design of temporary buildings , and the continuity and integrity of components should also be considered. Components assembly drawings should be drawn, and the materials, quantities, quality of each component and connector and the precautions during assembling should be listed.

3.9 The overall stability should be considered on the foundation of temporary building. The foundation of light steel structure temporary building with two or more floors shall adopt concrete independent foundation or concrete strip foundation.

3.10 The temporary building foundation should be designed based on the superstructure load and geological conditions. The strength level of foundation concrete should not be lower than C20; the strength of strip foundation blocks should not be lower than MU5, and the strength of mortar should not be lower than M5.

3.11 The masonry structure of the temporary building should be designed in accordance with the GB50003 in "Code for Design of Masonry Structures", and energy-saving and thermal insulation measures should be taken.

4. Electromechanical design

4.1 The lighting design of the temporary building should comply with the relevant provisions of the current National Building Lighting Design Standard GB50034 and the Civil Building Electrical Design Code JGJ16; the power distribution design should fully consider the functional requirements and should comply with the relevant provisions of the current national low voltage power distribution design Code GB50054 and the Technical Specification for Temporary Electricity Safety at Construction Sites JGJ46.

4.2 The lighting of temporary buildings should adopt the energy-saving light sources and energy-saving accessories, and the lamp should choose the green environmental products.

4.3 Evacuation staircases of multi-storey temporary buildings and evacuation inner walkways over 20 meters shall set up the evacuation instructions and emergency lighting.

4.4 When using a single-phase power supply for each temporary building, a switchgear that can disconnect the phase and neutral wires at the same time should be set up; the short circuit and overload protection appliances should be installed in the branch circuit. When the lighting distribution box is located outside the house, the protection level of the distribution box should not be lower than IP54.

4.5 As for the office room, except for special sockets, one 2- or 3-hole safety socket should be installed every 5 m2; special sockets should be provided for air conditioners. The lighting of the dormitory room should use 36V and below voltage, there is no socket in the dormitory, and special circuits for air conditioners, electric fans, electric heaters, etc should be set.

4.6 Lighting and sockets should be powered separately. Special circuits should be adopted for electricity of air conditioning and heating facilities. Except for the lighting and air-conditioning circuits, the protective devices for other socket circuits should choose residual current protectors. When lighting and sockets are connected to the same circuit, the residual current protector should be selected as the protective device of the circuit.

4.7 The wiring of the distribution line in the temporary building can be protected by metal pipes or plastic pipes and plastic trunking. The wall thickness of concealed metal pipe should not be less than 1.5mm, the wall thickness of concealed plastic pipe should not be less than 2.0mm; when exposed, plastic pipe and plastic wire trunking should be selected as Flammability class B1 material.

4.8 The electrical facilities in the bathroom should meet the safety of electricity consumption. Cable ducts should not be laid in Zones 0 and 1. It should not be laid in Zone 2 either. The lighting must use waterproof lamps and switches.

4.9 The grounding form of the low-voltage power distribution system of the temporary building shall adopt the TN-S system. The lightning protection and grounding design of temporary buildings should meet the relevant regulations of the current National Building Code for Lightning Protection Design GB50057, Design Code for Civil Buildings Electrical JGJ16, and Technical Specification for Temporary Electricity Safety at Construction Sites JGJ46.

4.10 A equipotential connection shall be provided in the temporary building, and a local equipotential connection shall be provided in wet places such as toilets and bathrooms with bathing facilities. The minimum allowable cross-section of equipotential connection lines shall comply with the relevant provisions of the Design Code for Civil Buildings Electrical JGJ16.

4.11 The design of the integrated wiring (including the network) of the temporary building shall comply with the relevant provisions of the "Engineering Design Specifications for Integrated Wiring Systems" GB50311.

4.12 The water supply pipe introduced into the temporary building can be provided with a water meter as required. Floor drains such as toilets and washrooms shall be provided with floor drains, and the depth of the floor water seal shall not be less than 50mm. Domestic water should use water-saving appliances with water efficiency level 2 and above.

4.13 Where freezing may occur, anti-freezing measures shall be taken for water supply, drainage pipes and related facilities.

4.14 The fire protection and explosion protection of the temporary warehouses that store flammable and explosive dangerous goods shall meet the requirements of the relevant sections of the "Code for Design of Automatic Fire Alarm Systems" GB50116 and "Code for Design of Electrical Devices in Explosive Dangerous Environments" GB50058.

5. Material requirements

5.1 Materials for temporary building should meet the requirements of current national, industry and local standards, and structural components should be selected from energy-saving and environmentally-friendly products. It is strictly forbidden to use products eliminated by the state and Beijing.

5.2 The steel used for the load-bearing structure of the dismantled light steel structure prefab house shall comply with the requirements of "Carbon Structural Steel" GB / T700 and "Low Alloy High Strength Structural Steel" GB / T1591 and shall have tensile strength and elongation , Yield strength, cold bend test and sulfur and phosphorus content testing documents. The material should be the same grade, and the welding structure should still have quality certification documents for carbon content.

5.3 The steel used for the load-bearing structure of container houses shall comply with the requirements of "Continuous Hot-Dip Galvanized Steel Sheet" GB / T2518, and shall have tensile strength, elongation, yield strength, cold bending test and sulfur and phosphorus content testing documents. The material should be the same grade, and the welding structure should still have quality certification documents for carbon content.

5.4 As for the galvanizing amount of steel members of container houses, it should not be less than 100g / m² on both sides of main steel beams and steel columns, and no less than 80 g / m² on both sides of secondary beams and purlins.

5.5 The building components of office and dormitory buildings shall use Class A materials with burning performance. When a metal sandwich panel is used, its core material shall have a flammability rating of Class A.

5.6 Flammable and explosive dangerous goods warehouses, combustible materials warehouses, processing rooms, generator rooms, substation rooms, kitchen operation rooms, boiler rooms and other temporary buildings should use combustion performance class A materials.

5.7 Indoor load-bearing floors and indoor ceilings shall use Class A materials of flammability rating.

5.8 The external door should be a steel door with fire and flame retardant function.

5.9 Exterior windows should be energy-saving and heat-insulating windows, and it should be double-glazed.

5.10 The total thickness of the metal sandwich panel used for the external wall of the container house should not be less than 75mm, the thickness of the steel plate (including the coating thickness) should be not less than 0.4mm; the thickness of the roof insulation layer should not be less than 100mm, and the thickness of the roof steel plate (including the coating thickness ) Should be not less than 0.4mm.

5.11 The total thickness of color steel sandwich panels used for the external walls and roofs of removable light steel structure prefab houses should not be less than 75mm, and the thickness of steel plates (including coating thickness) should not be less than 0.3mm.

5.12 The main structural connection of prefabricated container houses should be selected with high-strength hexagon bolts, nuts, and washers in accordance with GB / T 1228 ~ 1231.

5.13 The coating material and thickness of the coating should meet the requirements of the product design drawings. When the design has no requirements for the coating, the total thickness of the dry paint film of the main structure of the temporary building: the outdoor should not be less than 60µm and the indoor should not be less than 40µm , The allowable deviation is -5µm; the total thickness of the dry paint film of the main structure of the container house: the outdoor should not be less than 30µm, and the allowable deviation is -5µm.