Fabrication requirements of steel structure temporary prefab house

- 15 Apr 2020

- steel structure

1. General provisions

1.1 The temporary building manufacturer shall have an effective enterprise quality management system to ensure the controllability and traceability of the production quality.

1.2 The materials shall be green, low energy consumption or renewable, and meet the requirements of relevant standards.

2. Processing

2.1 The galvanized steel structure assembly and welding parts of container house shall be repaired with special primer, and then the operation of finishing coat coating process shall be carried out.

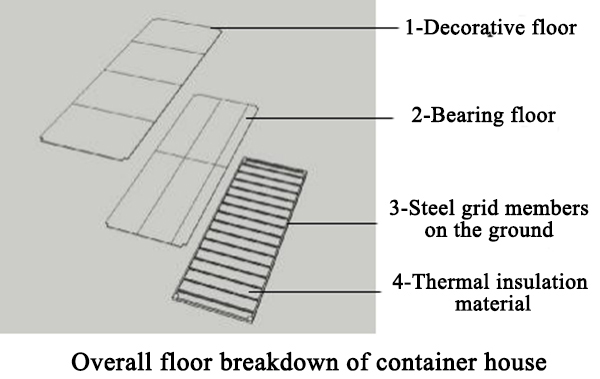

2.2 The thermal insulation material, load-bearing floor, decorative floor, etc. of the floor of the container house shall be integrated with the steel grid components of the floor to form the overall floor。

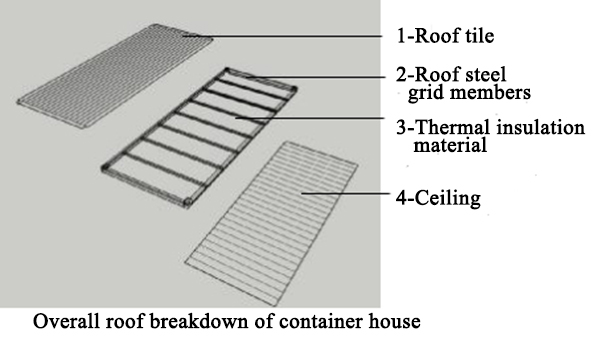

2.3The roof tiles, thermal insulation materials, ceilings, etc. of the container house roof shall be integrated with the roof steel grid components to form the overall roof.

2.4 The overall roof of the container house shall be reserved with electrical access, and the electrical connection with protective measures shall be equipped。

2.5 Effective sealing measures shall be taken for the overall roof of the container house to avoid rainwater leakage. For areas with high rainfall intensity, slope roof shall be added to the overall roof of the original box house.

2.6 Special functional parts of the box house, such as supporting toilets and staircases, should be made in the factory.

2.7 The main components such as the floor and roof of the prefabricated container house shall be standardized. The structural steel frame shall be pre assembled into steel grid components by welding or bolt splicing in the factory. And the assembly connection holes shall be reserved.

2.8 The beam, column and other structural components of the light steel structure room shall be prefabricated in the factory, and shall meet the installation requirements of site bolt connection, and shall not be welded.

2.9 The steel structure of the removable light steel structure room shall be protected by the paint meeting the environmental protection requirements. After the steel members are coated and dried, the appearance color shall be uniform. The surface shall be flat and smooth, without sagging, wrinkling, bottom exposure, bubble, pinhole, crazing, falling off and dirt.

2.10 the enclosure wallboard of the container house and the detachable light steel structure prefab house shall be modular design and manufactured in the factory, and shall not be cut on site.

2.11 the appearance quality, specification, dimension, allowable deviation and bonding performance of the metal sandwich panel of the box house and the removable light steel structure movable house shall meet the relevant requirements specified in the metal surface thermal insulation sandwich panel for building.

3. Plane layout

3.1 The site selection of temporary buildings shall be scientific and applicable, and meet the requirements of green construction management. It should not be built in dangerous areas such as landslide, collapse, debris flow, FT flood, etc. It should avoid water source protection area, reservoir flood discharge area, air vent with strong wind force, depression prone to water accumulation, etc., and organize drainage design within the site.

3.2 There should be no less than 2 emergency exits within the land area of temporary buildings, which should be arranged in different directions. And the width of the exits should be able to ensure the smooth access of fire trucks.

3.3 The office area and living area of the construction site shall be set separately from the construction area, and corresponding isolation measures shall be taken, and signs such as guidance, warning, positioning and publicity shall be set.

3.4 The office area and living area should be located outside the falling radius of buildings and the mechanical operation radius of tower cranes. If it can not meet the requirements, safety protection design shall be carried out.

3.5 Safe distance shall be kept between the temporary buildings and the overhead open power lines, and they shall not be arranged in the high-voltage corridor.

3.6 Office room (office, meeting room, reference room, etc.) and living room (dormitory, canteen, dining room, toilet, bathroom, sports room, etc.) shall be set at the construction site.

3.7 The construction site shall be equipped with closed construction waste station. The office area and living area shall be provided with closed garbage containers. The distance between canteen, toilet, garbage station and other pollution sources should not be less than 15m, and should not be set at the downwind side of the pollution source.

3.8 If the total building area of temporary buildings is greater than 1000m2, temporary outdoor fire water supply system shall be set. When the construction site is within the 150m protection range of municipal fire hydrants, and the number of municipal fire hydrants meets the requirements of outdoor fire water consumption, temporary outdoor fire water supply system may not be set.

4. Fire prevention distance

4.1 The fire separation distance between the temporary buildings in the non construction area and the construction in progress shall not be less than 10m; the fire separation distance between the inflammable and explosive dangerous goods warehouse and the construction in progress shall not be less than 15m; the fire separation distance between the combustible material storage yard and its processing yard, the fixed hot work yard and the construction in progress shall not be less than 10m.

4.2 The fire separation distance of main temporary buildings and temporary facilities on the construction site shall not be less than the provisions of table 4.2. When the office buildings and dormitories are arranged in groups, the fire separation distance can be reduced appropriately, but shall meet the following requirements:

The number of temporary buildings in each group shall not exceed 10, and the fire separation between groups shall not be less than 8m;

Table 4.2 Fire separation distance of main temporary buildings and temporary facilities on the construction site(m)

| Name spacing | Office and dormitory | Generator room, power transformation and distribution room | Combustible material warehouse | Kitchen operation room, boiler room | Combustible material storage yard and its processing yard | Fixed hot work site | Inflammable and explosive dangerous goods warehouse |

|---|---|---|---|---|---|---|---|

| Office and dormitory | 4 | 4 | 5 | 5 | 7 | 7 | 10 |

| Generator room, power transformation and distribution room | 4 | 4 | 5 | 5 | 7 | 7 | 10 |

| Combustible material warehouse | 5 | 5 | 5 | 5 | 7 | 7 | 10 |

| Kitchen operation room, boiler room | 5 | 5 | 5 | 5 | 7 | 7 | 10 |

| Combustible material storage yard and its processing yard | 7 | 7 | 7 | 7 | 7 | 10 | 10 |

| Fixed hot work site | 7 | 7 | 7 | 7 | 10 | 10 | 12 |

| Inflammable and explosive dangerous goods warehouse | 10 | 10 | 10 | 10 | 10 | 12 | 12 |

Note 1. The fire separation distance of temporary buildings and temporary facilities shall be calculated according to the minimum distance between the outer wall sideline of temporary buildings or the sideline of storage yard, operation field and operation shed. If there is a protruding combustible component on the outer wall of temporary buildings, it shall be calculated from the outer edge of the protruding combustible component.

2. When the outer wall of the adjacent higher side of the two temporary buildings is firewall, the fire separation distance is not limited.

3. If not specified in this table, it can be determined according to the fire separation distance of temporary buildings and temporary facilities with the same fire risk.

5. Fire lane

5.1 The distance between the temporary fire lane and the temporary building shall not be less than 5m, and shall not be more than 40m. When the roads around the temporary building meet the requirements of fire truck traffic and fire fighting and rescue, the temporary fire lane may not be set.

5.2 The setting of temporary fire lane shall meet the following requirements:

5.2.1 The temporary fire lane should be circular. If it is difficult to set the circular lane, a return yard with a size of not less than 12m × 12m should be set at the end of the fire lane.

5.2.2 The clear width and clearance height of the temporary fire lane shall not be less than 4m.

5.2.3 The right side of the temporary fire lane shall be provided with the direction sign of the fire truck.

5.2.4 The subgrade, pavement and lower facilities of the temporary fire lane shall be able to bear the traffic pressure and working load of the fire truck.

5.2.5 more than 10 temporary buildings arranged in groups shall be provided with ring temporary fire lane. If it is really difficult to set the ring temporary fire lane, in addition to the provision of return yard in accordance with article 5.3.2 of this specification, the temporary fire rescue site shall also be set in accordance with article 5.3.4 of this specification.

5.3 The temporary fire rescue site shall be set up in accordance with the following provisions:

5.3.1 The temporary fire rescue site shall be set on the long side of the temporary building site arranged in groups.

5.3.2 The width of the temporary rescue site shall meet the normal operation requirements of the fire truck and shall not be less than 6m; the clear distance from the temporary building shall not be less than 2m and shall not be more than 6m.

6. Installation, acceptance and use requirements

6.1 General provisions

6.1.1 Before the temporary buildings enter the site, the user shall check the installation data, and the formal construction can only be carried out after they meet the requirements.

6.1.2 The quality of components must be inspected and accepted before installation.

6.1.3 The foundation and embedded parts shall be accepted before the installation of temporary buildings. Foundation concrete strength reaches the design strength Installation can only be carried out when 70% of degree.

6.2 Installation requirements

6.2.1 Before the installation of temporary buildings, the technical director of the installation unit shall disclose the construction procedures, quality, safety and other technical information to the workers according to the construction scheme, and explain the key control points. During the installation, the key control points shall be confirmed to be qualified before the construction can continue.

6.2.2 The installation of container house shall meet the following requirements:

① When in place, it is better to use crane and other lifting equipment. When a large area of box opening may cause hoisting deformation, special hoisting frame or reinforcement shall be used for hoisting.

② Steel wire ropes, shackles, hooks and other lifting appliances for hoisting shall not exceed their rated allowable load. Special machines and tools shall meet the construction requirements and shall be inspected to be qualified.

③The installation sequence of box should be expanded from side to side in plane. When installing, adjust the elevation first, then adjust the center displacement, and finally adjust the vertical deviation.

④ The hoisting and installation of the box body shall be carried out in a reasonable sequence, and temporary supports or other temporary measures shall be provided if necessary.

6.2.3 The anchor bolt of removable light steel structure movable house column base shall be positioned by reliable method. Besides measuring the right angle side length, the diagonal length shall also be measured. Before structure installation, the space position of anchor bolt shall be checked to ensure that the plane size and elevation of foundation and top surface meet the design requirements.

6.2.4 The columns, beams, roof trusses, supports, stairs, walkways, awnings and other main components of the steel structure of temporary buildings shall be corrected and fixed immediately after being installed in place.

6.2.5 Temporary buildings shall be installed according to the requirements of design documents to ensure reliable connection, and waterproof treatment shall be done for roof and window. In case of severe weather such as strong wind, heavy fog, rainstorm, lightning, etc., the operation shall be stopped, and the installed enclosure materials shall be protected to prevent falling off.

6.2.6 After the completion of installation, self inspection shall be carried out for the whole project to ensure the construction quality of the project.

6.3 Inspection and acceptance

6.3.1 The detection of installation deviation shall be carried out after the structure forms spatial stiffness unit and is connected and fixed.

6.3.2 The installation and construction of divisional and subdivisional works of temporary buildings must meet the design requirements and product quality acceptance standards.

6.3.3 The temporary buildings shall be self inspected by the installation unit. After passing the self inspection, the user shall organize the supervision unit and installation unit to carry out the installation quality acceptance according to Appendix A. the temporary buildings can be delivered for use only after passing the acceptance.

6.3.4 Removable light steel structure movable house or container house shall be provided with quality certificates.

6.4 Safety requirements for use

6.4.1 The user of temporary buildings shall establish and improve the use management system of safety and security, health and epidemic prevention, fire control, living facilities, etc.

6.4.2 For the use of temporary buildings, emergency plans for wind, flood and snow disasters shall be established; before the storm, flood and snow, comprehensive inspection shall be carried out and reliable reinforcement measures shall be taken if necessary.

6.4.3 During the use of temporary buildings, the design use function shall not be changed, and the use load of the floor shall not exceed the design value; when the use load of the floor exceeds the design value, the structure shall be evaluated for safety. Cantilevered corridor is not suitable for dormitory.

6.4.4 During the use of temporary buildings, it is not allowed to open holes, drill holes or change the structure at will, and it is not allowed to dismantle the partition wall and enclosure structure components without permission.

6.4.5 When installing hanging parts on the wall of temporary buildings, the requirements of structural stress shall be met.

6.4.6 Temporary buildings shall be installed with heating facilities, and the original design circuit shall not be changed without permission. It is strictly prohibited to connect wires without permission, use electric appliances without permission, and use open fire for heating.

7. Demolition, transportation, maintenance and storage

7.1 General provisions

7.1.1 No other work shall be carried out in the demolition area of temporary buildings. Fences shall be set for isolation, and eye-catching warning signs shall be set.

7.1.2 Temporary buildings shall be demolished in accordance with technical code for safety of building demolition Engineering (jgj147) and relevant management regulations of Beijing. Before construction, technical scheme for demolition and emergency plan shall be prepared.

7.1.3 in case of severe weather such as strong wind, heavy fog, rain and snow and severe haze (red warning), the demolition of temporary buildings shall not be carried out.

7.2 Dismantle

7.2.1 The user shall be responsible for cutting off and transferring various pipelines that affect the demolition safety of temporary buildings.

7.2.2 the removal sequence of temporary buildings shall follow the principle of first installing components and then removing, and then installing components and first removing. It is forbidden to carry out three-dimensional cross operation during demolition construction.

7.2.3 All operators on the roof must use fall arrester and safety rope for reliable connection.

7.2.4 in any case, it is forbidden for the operator to stand on the component and remove it by shaking, prying or smashing the steel frame with a sledgehammer.

7.2.5 the removed bolts, connectors and removal tools shall be properly kept and placed, and shall not be scattered on the operation platform to avoid falling during lifting.

7.2.6 before lifting and removing the components, check whether all the connecting parts between the panel and the steel frame have been removed. The welding parts shall be removed by gas cutting or toothless saw. The panel, steel frame or integral box shall not be lifted until it is confirmed that there is no connection between the panel, steel frame or integral box and other structures.

7.2.7 the use of open fire shall be avoided as far as possible when dismantling components. If it is necessary to use open fire, it must be carried out in strict accordance with the provisions on the use of fire in construction operations.

7.2.8 Dismantle temporary buildings, minimize material damage and improve the turnover rate of semi-finished products.

7.2.9 For civilized construction, the site shall be cleaned timely and the garbage shall be removed after the demolition.

7.3 Stacking

7.3.1 Buildings and components shall be arranged reasonably according to the construction sequence and site conditions, and the stacking area shall be solid, flat and dry, with drainage measures.

7.3.2 The stacking height of the container house shall not exceed two floors, and reliable temporary connection shall be made. The structural members shall be placed on the support seat stably. When the members are stacked horizontally, pad wood shall be added at the bottom and between layers. Roof truss, truss, beam, etc. shall be stacked vertically.

7.4 Transportation, maintenance and storage

7.4.1 Temporary buildings and materials shall be transported in accordance with relevant national and local specifications, and vehicles shall be selected according to the length, height and weight of buildings and components.

7.4.2 Before transportation, excess welding parts and auxiliary parts on the external surface of temporary buildings and components shall be removed.

7.4.3 The temporary building components shall not shake, deform or damage the surface coating during transportation.

7.4.4 Obvious reflective signs shall be pasted on the box house during transportation to reflect the specification range of the box.

7.4.5 After the temporary buildings and accessories are removed, they shall be cleaned in time, inspected according to Schedule B, and the deformed and damaged parts shall be repaired.

7.4.6 Spare parts can be bundled, boxed and bagged, and shall be stored by category in storage. And according to the characteristics of various materials to carry out zoning management, do a good job in rain, moisture, fire and other related measures.

7.4.7 The container house can be stacked and managed according to the functional room, and can be stored in full box or packed in box.

8. Green construction requirements

8.1 General provisions

8.1.1 The quality of raw materials and semi-finished products for the production and processing of temporary buildings shall meet the requirements of relevant national green energy conservation standards.

8.1.2 The production and processing unit of temporary buildings shall carry out green design of products in accordance with the current relevant national standards and the requirements of the general contractor.

8.1.3 The design, fabrication, layout, installation, demolition, transportation and storage of temporary buildings shall be consistent with the green construction objectives of the project.

8.2 Green production and construction

8.2.1 The production link of temporary buildings shall be aimed at energy conservation, consumption reduction and pollution reduction. In the production process, the generation and discharge of waste and pollutants shall be eliminated to realize rational utilization of resources and reduce the harm of industrial production activities to human beings and the surrounding environment.

8.2.2 The temporary production buildings shall be painted in the closed spray booth with air supply and filter exhaust, and the environmental protection type paint shall be used.

8.2.3 The production of temporary buildings shall pay attention to the integrated design, and the structural processing, thermal insulation materials, decorative materials and electrical systems shall be prefabricated in the factory to reduce the construction on site.

8.2.4 Energy and water saving instruments shall be used at the construction site, and warning signs shall be set as required. The allocation rate of water-saving appliances shall reach 100%.

8.2.5 Building materials and products produced within 500km from the construction site should be selected for temporary buildings, and energy-saving materials and products should be used. The material transportation method should be scientific to reduce the transportation loss rate. Measures shall be taken to reduce the generation of construction waste in accordance with the relevant provisions of the construction waste emission reduction treatment and green construction, and centralized classified management shall be implemented to promote comprehensive utilization.

8.2.6 Temporary buildings shall take effective energy conservation and consumption reduction measures in combination with natural conditions such as sunshine and wind direction, and reasonably adopt natural lighting, ventilation and external window shading facilities. The body shape should be regular, with natural ventilation and lighting, and meet the energy saving requirements. Cold proof measures shall be taken for external doors in winter and sunshade measures shall be taken for external windows in summer.

8.2.7 Special warehouses shall be set up for oil, chemical solvents and other items stored on the construction site, and anti leakage treatment shall be done on the ground. Filter screen shall be set for the water pipeline in canteen, washroom and shower room, and oil separator shall be set in canteen. Septic tank shall be set for the fixed toilet on the construction site. The oil separator and septic tank shall be provided with anti-seepage treatment, and shall be regularly cleaned, transported and disinfected.