National Grand Theater of Chinese Steel Structure Engineering

- 20 Feb 2020

- steel structure

1. Basic situation of the project

Project location: No. 2 West Chang'an Street, Xicheng District

Construction cost: 3.3 billion yuan

Building area: 21.944 million m2

Building height: 46.285 meters

Structure type: frame-shear wall concrete shell steel structure

Commencement date: December 13, 2001

Completion Date: September 25, 2007

2. Project Introduction

2.1 Project Overview

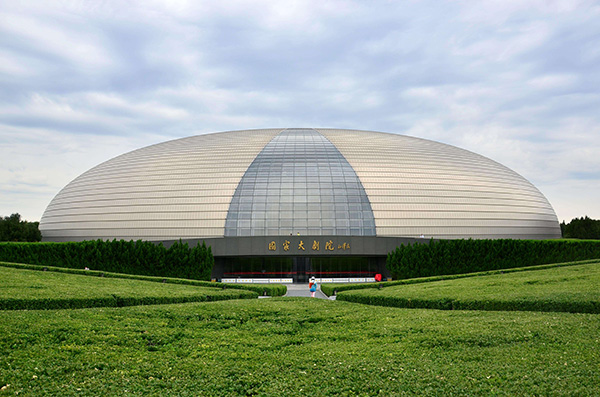

The National Grand Theater is a large-scale cultural facility invested and built by the Chinese government for the 21st century. It is one of the highest art performance centers in China, a world-class large-scale art hall, and one of Beijing's landmark buildings.

2.2 Characteristics of the project

The overall planning and design of this project combines the three main elements of water, green space and humanized architecture, to preserve the entire green area to the maximum extent, create a spacious and open urban garden, and promote the improvement of the urban ecological environment in the west side of Tiananmen. Its unique design concept and advanced postmodern appearance attract the attention of every passerby and attract worldwide attention.

2.3 Engineering Difficulties

The project is located in the center of the capital, with strict traffic or other temporary controls, and there are many uncertain interference factors. The engineering volume is huge and the technology is complex, including civil engineering, electromechanical, shell steel structure, metal roofing, stage equipment, lighting and sound, weak electricity, fire protection, outdoor gardening, roads and greening, and many other majors. The major equipment and pipelines are large and interspersed. There are many operations and the requirements for on-site organization, coordination, and management are extremely high. The structure of the building is staggered with flat and vertical layouts, demarcations, irregular layers, and no standard structural layer, which is not conducive to the use of formwork and the flow of plane partitions, and it is difficult to organize construction. The concrete structure is a very complex frame-shear wall structure. The flat and vertical layouts are staggered, there are many curved walls and large-sized components, and the structural columns are mostly stiff columns. All three theaters have large spans and high volleys. Profile steel-concrete composite structure.

2.4 Engineering Technology Innovation Points

The project has many latest green technology innovations in the construction industry at home and abroad. The deep foundation pit support project has pumped tens of millions of cubic meters of groundwater. Environmental protection construction technology has promoted the protection of groundwater resources in Beijing. It is a non-ellipsoidal sphere, with a large span, complicated technology, and difficult space positioning and installation. Its installation technology has reached the international advanced level of technology. The large-scale shell titanium metal roofing project has great innovations and breakthroughs. The decorative board's non-penetrating metal waterproof roof system and floating block glass curtain wall support system have reached the international advanced technology level; in Beijing, the environmentally friendly and sound-proof aluminum-magnesium-manganese alloy waterproof board was applied to a large-area three-dimensional super-oval roof for the first time. ; The inside of the shell roof is made of green environmentally friendly spraying material with plant fiber as the raw material to achieve the functions of sound absorption, sound insulation, moisture resistance and noise reduction; the shell roof mushroom lights all use low energy consumption and high light efficiency LED diode light emitting technology; the landscape pool uses advanced central liquid Cold and heat source environmental system, make full use of geothermal clean energy to achieve "winter Ice, summer is not long algae, "truly a zero-consumption, zero emissions, zero pollution.

3. Analysis of the main economic and social benefits after the project is put into use

By adopting a series of new technologies and materials, this project has directly saved more than 20 million yuan in costs for the project and achieved good economic benefits. With beautiful shapes, excellent quality and perfect functions, it has effectively guaranteed the success of the international performance season. After the official performance of the National Grand Theater, it was verified that the various equipment systems worked well and that all architectural functions could meet the special requirements of the Grand Theater as the highest art performance center in China. It has been widely praised by the owners, actors, and audiences, and it has achieved good social benefits.