Prevention for quality common problems of steel structure project

- 13 Aug 2019

- steel structure

In order to ensure the quality of steel structure and civil works meets the predetermined standards, the following preventive measures are taken for the common quality problems that often occur in engineering:

1. Prevention and control measures for common quality problems in civil engineering projects

1.1 Steel welding:

The welder needs to be certified to work; before the formal welding, the test welding must be carried out according to the regulations; after each batch of steel bars is welded, self-test should be carried out, and random sampling should be carried out according to the regulations; when checking the quality of the weld, the type of the welding rod should be checked at the same time.

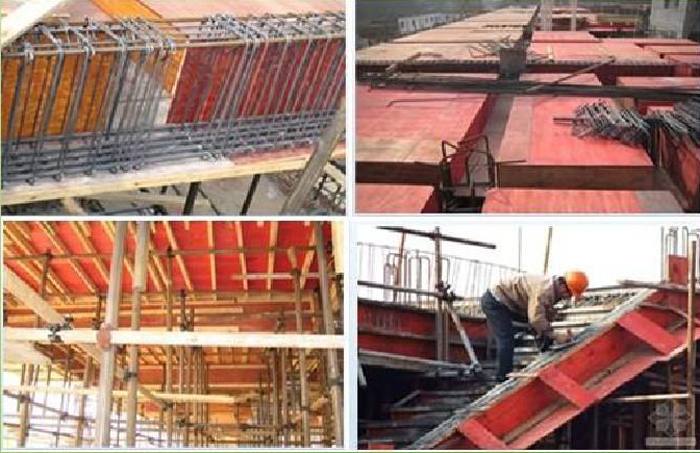

1.2 Quality problems that may occur in the template project:

The axis, the elevation deviation, the template section size deviation, the template stiffness is not enough, the support is not strong, and the hole center line displacement is reserved.

Precaution:

1.2.1 Draw a key axis control chart, each layer checks the axis elevation once, and the verticality is controlled by the theodolite.

1.2.2 Draw a reserved and pre-embedded map, and conduct a random check on the basis of self-test to see if the reservation and pre-buried meet the requirements.

1.2.3 Important templates must be designed and calculated to ensure sufficient strength and rigidity.

1.3 Possible problems with the concrete project:

Honeycomb, pockmark, exposed ribs, axis shift, skewed bumps.

Precaution:

1.3.1 The template is clean and free of debris.

1.3.2 The layer must be evenly vibrated and compacted to prevent leakage vibration. Each layer of concrete should be shaken until the bubble is removed.

1.3.3 Before pouring the concrete, check whether the position of the steel bar and the protective layer are accurate, fix the mortar block, and avoid the vibrating bar from striking the steel bar when vibrating. The demoulding time should be determined according to the test results of the test block to prevent premature demoulding.

1.3.4 When pouring concrete, the template, bracket, caulking, etc. should be observed, the template should be fixed firmly, and the column clamp should be set outside the column template.

2. Prevention and cure measures for common problems of steel structure engineering quality

2.1 The deformation caused by welding during assembly, it exceeds the allowable value.

Precautionary measures: welders need to be certified to work; before the formal welding, test welding must be carried out according to the regulations; after the first welding of each batch of steel plates, the welding process qualification should be carried out, and random sampling should be carried out according to the regulations; when checking the quality of the welds, Also check the electrode type.

2.2 When the material is stacked, it will be damaged and deformed due to collision.

Precautionary measures: Materials should be stored in accordance with regulations, designated areas, and barbaric loading and unloading is strictly prohibited.

2.3 During transportation, due to collision, damage, bending and deformation are caused.

Precautionary measures: Bundle firmly during transportation, reduce collision and squeeze. It is inevitable to straighten on the spot.

2.4 There is a gap between the steel column and the foundation.

Precautionary measures: Perform a secondary grouting method and add a bulking agent.

2.5 The rust prevention is not strict, the paint is not evenly painted, and the foundation is exposed.

Precautionary measures: Focus on the control of shot blasting, and reach the standard to spray anti-rust paint.