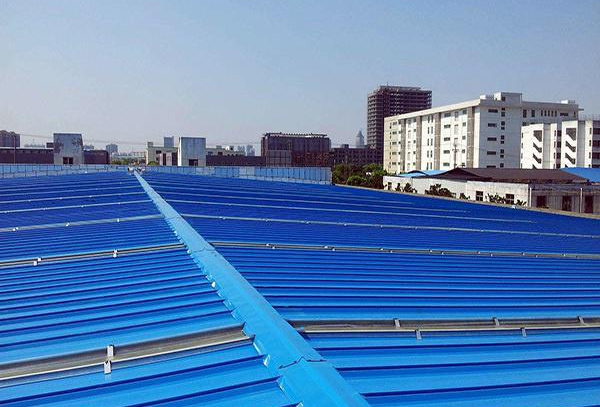

Steel structure waterproof material and construction scheme

- 10 Jul 2019

- steel structure

Steel structure roof waterproofing is an important project in construction. The quality of waterproof materials is not good, or the waterproof construction steps are not strict enough, all will lead to the leakage of roof surface. Therefore, we must pay attention to what is the waterproof material of steel structure, and how to implement the waterproof construction scheme of steel structure. This will further ensure the construction effect of the entire decoration. The following brings specific knowledge of steel structure waterproofing, and interested friends can look down.

One, What are the steel structure waterproof materials?

Steel structure roof waterproofing is an important construction project in the building. There are many waterproof materials. What are the specific steel structure waterproof materials? Here are a few of the more common ones:

1. Silicone glue

Silicone rubber is a kind of waterproof material similar to ointment. Silicone rubber is mainly divided into four types: deacetic acid type, dealcoholized type, deaminated type and de-propyl type. After contact with moisture in the air, it will be Curing into a tough rubber-like solid. the material is solidified, the bonding strength is low, and the waterproof effect is relatively general.

2. Polyurethane waterproof coating

The polyurethane waterproof coating is an isocyanate group-containing prepolymer which is processed by a polymerization reaction and a mixing process. This waterproof coating has strong adhesion to the base surface and it is used for steel structure roofing with excellent roof waterproofing and strong adhesion. At the same time, it also can be applied to the bonding of some polymer coils, which is a very good bonding material.

3. Butyl rubber waterproof adhesive tape

Butyl rubber waterproof sealing adhesive tape is mainly processed from butyl rubber and polyisobutylene. This waterproof material is made of high quality special polymer material and processed through special process. The butyl rubber waterproof adhesive strip structure waterproof material is very environmentally friendly, and is an environmentally friendly solvent-free sealing adhesive material.

4. SBS coil

SBS coil is a kind of curlable sheet waterproof material, often referred to as thermoplastic elastomer waterproof material, which is an important variety in building engineering waterproof materials and has high temperature resistance. Therefore, the SBS coil is very suitable for the waterproofing of steel structure roofs, and is suitable for such high temperature areas where the sun is strongly radiated.

Summary: The above are some common steel structure waterproof materials. For the specific steel structure waterproof materials, there are still many on the market. Each waterproof material has its own advantages, and it is selected according to the material characteristics when selecting.

Two, Steel structure waterproof construction plan

Waterproofing of steel structures is a relatively complicated construction project, but someone do not know how to deal with the waterproof of steel structures. And we will explain the waterproof construction scheme of steel structure for your reference:

1. Construction process

Accept leveling layer → clean the base layer → prepare cement binder → make additional layer → base layer construction → protective layer → curing.

2. Construction steps

2.1 Laying waterproof film

For the waterproof construction of steel structures, the roof waterproofing films should be pre-rolled, and then the ends of the coils are rolled up in half. The prepared cement adhesive is then poured onto the substrate, and then evenly scraped off with a squeegee to remove the air inside the waterproof roll.

2.2 Waterproof joint treatment

For joints with steel structure waterproof roof, cement adhesive is used for bonding. When bonding, the additional layer joints should be staggered more than 5cm from the waterproof layer. And the width of the overlap is 8cm-10cm on the long side and 10cm-15cm on the short side. The adjacent short-side joints should be staggered by more than 100cm, and the angle between the wall and the ground is 30cm or more.

2.3 Waterproof protective layer construction

After the coil is pasted, a cement mortar with a thickness of 2 cm is placed on the protective layer, and it is divided into two times when it is applied. The second floor joint must be staggered more than 20cm until the protective layer is flat and then sprinkled for maintenance.

There are many things to be aware of in the waterproof construction of steel structures. The above steel structure waterproof construction plan, I hope to bring some help to everyone.

Three, Steelstructure waterproof construction precautions

1. Because the waterproof breathable film has no obvious flame retardant effect, it is necessary to avoid to use welding for the curtain wall connection during construction, and it is strictly forbidden to carry out open fire operation near the waterproof breathable film.

2. Laying waterproof breathable film should be selected according to the actual situation, it should use rockwool nail to fix waterproof breathable film and insulation cotton firstly. Then seal the rockwool nails with butyl tape to ensure complete coverage of the nail head.

3. Steelstructure waterproof construction should also pay attention to avoid penetration and opening on the waterproof breathable film, try to ensure the integrity of the waterproof breathable film. If it is necessary to open or penetrate it, the penetration and opening should be sealed with butyl tape.

4. For roof steelstructure waterproof construction, the waterproof breathable membrane is laid in the direction of the water flows. For the intersection of the aluminum alloy bracket and the waterproof breathable film, it needs to be sealed with butyl rubber strip.

5. Steelstructure waterproof construction, also should ensure that the corner code is clean, if the corner code passed through the waterproof breathable film, we should try to ensure the integrity of the waterproof breathable film. Also we also need to ensure the waterproof breathable film is completely sealed and that there are no bubbles.