Summary of common problems in steel structure

- 09 Sep 2019

- steel structure

We try to actively promote green buildings, vigorously develop light steel structure houses, improve the standards and quality of construction projects, improve the living environment of the people, and make the people live more peacefully and comfortably. For fresh things, everyone will definitely have all kinds of doubts. The following will solve these problems for everyone.

Question: What are the advantages of light steel construction over traditional homes?

Answer: Compared with brick-and-mortar houses, the light steel structure can avoid the waste of resources caused by earth-fired bricks. And because the wall thickness of the light steel structure is small, the effective use area can be increased compared with the brick-concrete structure. Compared with reinforced concrete houses, light steel structure can be recycled, and concrete can not be recycled, and it will definitely be construction waste in the future, causing environmental pressure. Moreover, the concrete takes a long time to be completely dried, so it is easy to cause indoor moisture, which is not conducive to human health.

Light steel structure has better seismic performance. Because the earthquake activity is left and right and up and down, the steel structure tightly connected by galvanized bolts constitutes a safe and stable box, and the wall will not collapse due to the shaking of the earthquake. Falling floor slabs endanger personal safety.

The dry construction method of light steel structure construction will not cause waste of water resources and save corresponding costs.

Question: the comparison between civil engineering and light steel structure houses?

| Performance | Light steel structure house | Traditional brick house |

|---|---|---|

| Insulation performance | The composite wall has low heat transfer, cool in winter and cool in summer, and the thermal insulation performance of 140mm thick light steel structure composite wall is equivalent to 610mm thick traditional brick-concrete structure, saving about 32%. | High heat conductivity, general insulation performance, high energy consumption |

| Moisture proof | The building is integrated with moisture-proof measures, no blind spots, and the wall is provided with one-way breathing paper, making the whole building a house that can breathe. | No overall moisture protection measures, poor air permeability |

| Seismic strength | The building has light weight and high toughness. Due to the good structure of the “cage” structure, the damage caused by the earthquake load is minimal. | Brittle structures are severely damaged under seismic loading |

| Fire-resistant level | The internal and external wall materials used can meet the fire rating requirements | Better |

| Structural span | Rich in structural form compared to cost time and span | Achieve large-span structure consumption materials, a single form |

| Construction period | Save half or more of the construction time compared to traditional brick-concrete houses, and they can be completed when they are completed. | Long construction period and can not construction in cold winter areas |

| Factory prefabrication | Lightweight, most of the structures such as the beam truss can be prefabricated at the factory. | Few prefabricated components |

| Recycle and re-use | Structural body components can be recycled and reused | Unable to recycle |

| Low carbon environmental protection | Renewable resources, and can be naturally degraded, zero pollution, zero emissions, no dust, noise during house construction | Generates a lot of construction waste, dust, noise and non-recyclables |

| Usage rate | The light steel structure composite wall is thin, and the room rate is higher than that of traditional buildings by about 18%. | The wall is too thick and the room rate is low. |

| Quick installation | The construction process is to assemble the prefabricated components of the factory, using clean and simple, no wet operation. | The construction process is complicated and requires a long maintenance cycle |

Question: Can light steel structure houses handle real estate licenses? What are the procedures for running the department?

Answer: Steel structure houses can not do real estate licenses, and has nothing to do with the house itself. There is a great relationship with the nature of the land. The policies in each region are different. Many of our customers have also applied for real estate licenses. Like many civil engineering projects, it is not always possible to carry out real estate licenses. This issue has a lot to do with the local government.

Question: How to install the heating equipment in the light steel structure house?

Answer: If it is an ordinary radiator, it can be fixed directly on the wall. If it is floor heating, the floor heating can be installed on the cement pressure plate, which is no different from the traditional building.

Question: Which installations are responsible for light steel structure houses?

Answer: If it is a large-scale light steel structure housing project, it generally does not include interior decoration, civil engineering without doors and windows, and without foundation and ground. In addition, the exterior is fully decorated, and the sound insulation and waterproof function has been completed. Additional items can also be added according to the special requirements of the owner.

Question: What is the general price of light steel structure houses?

Answer: There is a general offer for houses with ordinary shapes and no special structure. For houses with complex structural shapes and special requirements, it is not suitable for general quotation. Whether it is ordinary or has special requirements, the exact quotation will be calculated according to the drawings.

Question: Is there a relationship between the height and price of light steel houses? What is the general height?

Answer: There will be a certain relationship, because the difference in height will result in different materials usage and working hours. The height of each floor is generally 2.5-3.4 meters per floor. The price is higher than your design.

Question: What materials are mainly used on the second floor of light steel houses? Can it be shock-absorbing, soundproof and waterproof.

Answer: There are two ways to do the second floor of a light steel house. 1 Pour the concrete floor on the basis of the cement fiber board, and then lay the tile, wooden floor or carpet. 2 After the waterproofing treatment is done on the basis of the cement fiberboard, the wooden floor or carpet is directly laid. There is nothing wrong with both approaches to waterproofing. the sound insulation layer is also formed between the ceiling of the first floor and the second floor.

Question: What is the live load of the second floor and roof of a light steel house? What is the wall?

Answer: The wind pressure on the wall is 0.4KN/M2 (40 kg), the constant load on the roof is 0.35KN/M2 (35 kg), and the live load on the roof is 0.5KN/M2 (50 kg). This value is the design standard for the East China region. Different values will change. The ground live load on the second floor is 0.31-0.36KN/M2 (310kg-360kg). If you have special needs, we can increase or decrease your design.

Question: What is the market prospect of light steel villas?

Answer: According to the use situation of developed countries in the past century, combined with the current domestic penetration rate, the market prospect is very broad.

Advantages: (1) It can realize factory customized production and improve the living environment of human society. The light steel structure house can not only replace the traditional residential structure mode, but also completely use the industrialized production of building materials. It is an environmentally-friendly and energy-saving house that is made of steel, brick, steel and concrete. It is the 21st century to improve the living environment of human society. The best product.

(2) The construction speed is fast, the cycle is short, the efficiency is high, and it is not affected by the season, and the construction is all-weather.

(3) The waste utilization rate of the structure is 100%, which is a true environmentally friendly building material.

(4) China's construction industry will definitely develop into a housing manufacturing industry. With the increase of civil labor costs, the cost performance of light steel houses will increase in the future. Light steel houses are a very high-end product. At the very top of the world, his market prospects will get better and better in the next few decades, and there is a major historic opportunity for China's new rural construction.

Question: Will there be any safety hazards in the installation of water and electricity in light steel houses?

Answer: No, we have reserved water and electricity safety holes at the beginning of the design, so there is no hidden danger of water and electricity. Because all the circuits in the light steel house are laid through the line pipe, and the water pipe is pressed after the test is completed, there is no need to worry about the water circuit.

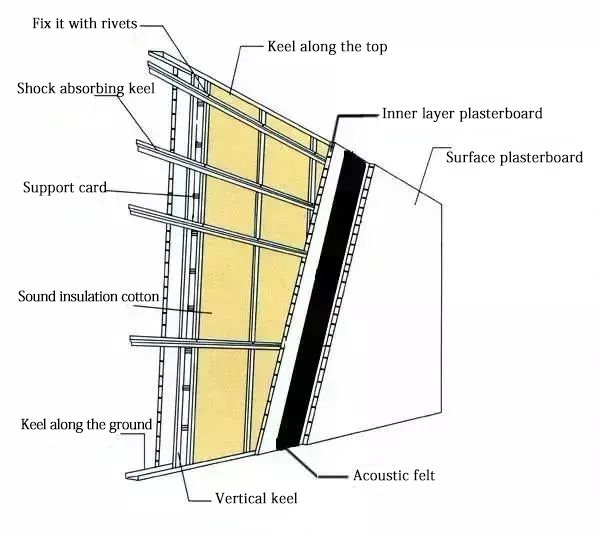

Question: How do you prove that the sound insulation of light steel houses is better than that of civil works?

Answer: The sound insulation effect is an important indicator for evaluating residential buildings. The light steel house system is better than the traditional civil structure. It has been concluded through strict testing by relevant departments and long-term foreign application. The reason why it is good is that the wall of the light steel house is composed of two layers of inner and outer double-layer tension plates, breathing paper, extruded board, glass wire insulation, interior wall panels and exterior wall metal carved panels. Into the insulation and sound insulation, especially the 16mm polyurethane foam used in the exterior metal carved panels is the best thermal insulation material in the country, so the sound insulation effect is better than the civil construction.

Question: Can light steel houses be used twice?

Answer: Yes, the advantage of light steel houses lies in its detachable mobility, and most of the main structures can be used multiple times.

Question: Does the light steel house provide warranty? How long is the warranty period?

Answer: Provide warranty and free warranty for one year without damage caused by human reasons.

Question: How long is the construction period of light steel houses? (300m2 as an example)

Answer: The main part of the construction party is responsible for 20-30 days from the construction to the end.

Question: What should first party provide before the construction of light steel houses?

Answer: According to the construction drawings, the basic manufacturing is completed and the strength of the construction is allowed, and the obstacles on the site are cleaned and the water passage is energized. If you need to apply for a real estate license, the preliminary procedures for opening and inspection must be improved in advance.

Question: What is the standard basis for the acceptance of light steel houses?

Answer: China issued the Technical Specification for Cold-Formed Thin-Wall Steel Structures in 2003.

Question: How is the area of irregular light steel houses calculated?

Answer: It is according to the area of the building occupied by the outer wall of the building. If the double layer is calculated by double layer, if the three layers are calculated by three layers.

Question: How is the area of irregular light steel houses calculated?

Answer: Calculate according to the area of the building occupied by the outer wall of the building. If the double layer is calculated by double layer, if the three layers are calculated by three layers.

Question: What is the height and span of a single-deck light steel villa?

Answer: Height and span are determined according to customer requirements and floor plan, no fixed size! Under normal circumstances, the height of the floor is about 3 meters, and the net span is within 7 meters.

Question: What is the bearing capacity of the double-story light steel house roof, can concrete pouring be carried out?

Answer: The ground bearing capacity of the second floor is generally 0.31-0.36kn/m2 (310kg-360kg), which can be used for concrete pouring.

Question: Can the small light steel villa be transferred as a whole?

Answer: Yes.

Question: Can the light steel house roof be treated with traditional tiles?

Answer: Yes, traditional tiles are fixed using our dry steel method using our light steel houses, which is not exactly equivalent to traditional construction methods.

Question: What is the difference between the thickness and strength of the same two floors and light steel houses compared to the second floor of a brick-concrete structure?

Answer: The thickness of the slab of the light steel house is greater than that of the brick-concrete structure; the strength meets the design specifications.

Question: What percentage of the loss of materials and accessories for light steel houses during secondary construction?

Answer: The size of the loss is closely related to the initial solution, and the loss ratio is between 10% and 50%.

Question: How much typhoon damage can be resisted by the bottom treatment of light steel houses?

Answer: According to the wind load conditions, the typhoon area can be strengthened on the connection, which can resist 13 winds and wind resistance: 40m/s.

Question: The materials and accessories used in light steel houses are all steel materials. Will this affect the communication of mobile phones?

Answer: No.

Question: Will there be cracks after the putty pieces are scraped together in the inner wall lining of the light steel house? How to deal with it?

Answer: There will be no cracks. Our inner wall gypsum board and inner structural board are staggered, and the joints of the outer gypsum board are covered with tape to effectively prevent cracks.

Question: What is the maximum allowable span of light steel houses? If the width exceeds this width, will the structure be changed?

Answer: The maximum allowable span of light steel houses is 10m. If this span is exceeded, the composite structure of various materials such as H-beam, square steel and light steel will be used to finally realize the load required by the design specification.

Question: How is the light steel house suspended? What is the construction process?

Answer: There is no difference between the ceiling of a light steel house and the ceiling of a traditional house. Firstly, the ceiling keel is installed, and the ceiling plate is installed next. It is more convenient in construction than the traditional building.

Question: The outer wall metal carved plate will have a male corner piece at the corner of the square corner, but the water will flow laterally and will flow into the wall in the corner piece. How to deal with it?

Answer: We perform rubberizing on the inner side of the male corner piece and the side of the male corner piece, and the double layer protection prevents the lateral flowing water from entering the inner layer of the structure.

Question: What system does the light steel house fall through?

Answer: Integrated falling water and free fall water.

Question: How to pack light steel houses when they are transported?

Answer: Light steel houses are shipped without packaging. When we distribute materials, we package the materials. The specific packaging method is designed according to the distance and transportation.

Question: Do light steel houses need or can be designed according to local wind loads, snow loads, earthquakes, etc?

Answer: It is necessary that different countries and regions have corresponding local standards. We design according to local standards.

Question: What maintenance is needed during the use of light steel houses?

Answer: Regularly check the house for leaks and cracks; replace the materials according to the characteristics and age of the materials.

Question: How many sqm can you install in a light steel house?

Answer: The space of the small cabinet is fixed, and the configuration of the light steel house is uncertain, so the estimated value is: a cubic steel house with 2.5-3 square meters. (small cabinet space: 2250 wide * 5800 long * 2300 high mm)

Question: How is the water supply of light steel houses solved?

Answer: Water supply and drainage pipes.

Question: What certifications do light steel houses have now?

Answer: CE certification, ISO quality management system, etc.

Question: What tools do you need to build a light steel house?

Answer: The main tools are: electric drills, cutting machines, air nail guns, etc. There are many kinds of tools, so they are not listed one by one. If there are customer inquiries, they can be specified for the process.

Question: After the light steel house reaches the service life, what should we do?

Answer: Recycling after disassembly, the recovery rate can reach 90%.

Question: How long is the construction period of light steel houses generally? Package installation?

Answer: The package is installed. The construction period is determined according to the difficulty of the project. About one square meter of work (one work and eight hours a day), the total working hours depends on the number of construction workers.

Question: What are the basic projects for light steel houses?

Answer: Positioning and releasing line -- earth excavation -- cushion formwork installation -- cushion concrete construction -- cushion formwork demolition -- basic brick masonry -- ground ring beam rebar processing -- ground ring beam rebar installation -- geosphere beam formwork installation -- concrete beam concrete construction -- removal of ground ring beam formwork -- earthwork backfilling.

Question: Can light steel houses be moved? Can the material be used twice?

Answer: Whether the movement is related to the initial design, if the design is immovable, then the latter cannot move. The material can be used twice.

Question: What is the spacing and size of the light steel keel?

Answer: Light steel keel specifications: 89 * 41 * 10mm thickness: 0.8mm, 1.0mm, 1.2mm; spacing between 406-610mm.

Question: How to make the installation of light steel houses convenient for customers?

Answer: The way of loading light steel houses is to pack the cabinets.

Question: What is the amount of steel used per square meter of light steel keel? How is it calculated?

Answer: Depending on the type of house, the keel wall thickness is different and the building area is different. Villa category: 24-35kg / square meter.

Question: What is the role of the steel mesh in the main project configuration list of light steel houses?

Answer: The ceiling is used. Uses: Support glasswool insulation.

Question: Will our materials be affected by termites?

Answer: No, the material of steel structure house is light steel. Only some of the materials are made of wood. The amount is small, and it is not solid wood, so it is rarely attacked by termites.

Question: Will the bolts and nails get rusted?

Answer: No. Qualified products are coated and protected against corrosion.

Question: Is there any harmful gas emission during the construction of light steel houses with interior decoration?

Answer: No, the materials used in light steel houses are environmental friendly materials and there is no harmful gas emissions.

Question: Can you compare the fire resistance of steel structure, masonry and reinforced concrete?

Answer: Reinforced concrete has fire-resisting time, The steel structure should be divided into fire-resistant parts to ensure the fire resistance, the column is 2.5 hours and the beam is 2 hours.

Question: What are the basic factors that determine the cost of a light steel villa?

Answer: First: wall structure; second: selected materials; third: type; fourth: house modeling.

Question: The light steel structure house is built by light steel keel. Can it effectively avoid lightning?

Answer: Yes, light steel houses have a special lightning protection structure.

Question: Can light steel houses be built on the water, and can the light steel keel directly mount in the center of the water?

Answer: Light steel houses can be built on the water, but light steel houses cannot be placed directly in the water.

Question: If the light steel house is fixed on the foundation, is there a solder joint? What is the stability?

Answer: There is no solder joint, it is firm and the stability meets the design specifications.

Question: Can light steel houses help build foundations? How is the fee charged?

Answer: Yes, but due to different reasons, the purchase of sand and gravel cement is difficult. Generally, Party A is responsible for the construction.

Question: What kind of material is the inner wall of the rough house of light steel house? If the decoration is done, is it possible to apply latex paint directly?

Answer: The interior wall of the rough room is generally OSB board. When decorating, it is necessary to fix a layer of gypsum board and then do interior wall treatment. Do not apply latex paint directly.