Ten Key Points of Quality Control of Steel Structure Project

- 02 Apr 2019

- steel structure

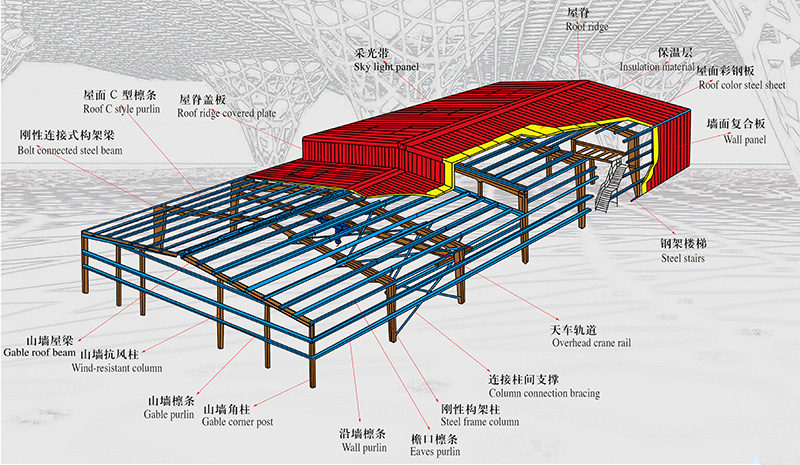

Steel structure is one of the more common structural forms in modern construction engineering. The application of steel structure engineering technology has become more and more widespread all over the world, and many advantages of steel structure have also been taken seriously, hence the application of steel structure engineering has also increased. This paper analyzes the technical requirements of steel structure engineering to strengthen the technical application and management of steel structure engineering to ensure the safety and reliability of the whole steel structure engineering.

Drawings are the basis for the construction of steel structures. The technical person in charge of the project should organize relevant technical personnel to review and digest the drawings. There are two purposes. Firstly, making all participating units familiarize with the design drawings, understand the engineering characteristics and design intent, find out the technical problems to solve, and formulate a solution.Secondly, solving the problems and reducing the errors of the drawings. At the same time, doing a good job in steel structure technology, the combination of construction and design, steel structure hoisting and civil construction, we well as steel structure and concrete structure prefabrication. What are the main points about the quality control of steel structure engineering in detailed below.

Quality Control of Steel Structure Project

1. Raw Material

1.1. Being Familiar with the drawings, summarizing the problems existing in the drawings, participating in the drawing review and design work; recording the types, specifications and performance of the materials used in the main components of the drawings in accordance with the current national standards and design requirements, and providing Product warranty, Chinese logo and test report.

1.2. The varieties, specifications and performances of high-strength bolts and connecting pairs, ordinary bolts, rivets, self-tapping screws, anchor bolts and nuts used between beams and beams, beams and columns shall conform to the current national Standard and design requirements, and providing product quality certification documents and test reports.

2. Steel Structure Accessories and Components Production

2.1. The Types, specifications and performance of steel products should conform to the current national product standards and design requirements.

2.2. The processing of the steel cutting surface shall be free of cracks, slag inclusions, delamination and 1mm missing edges.

2.3. When the steel component is processed, it will be deformed. In order to meet the requirements, it must be corrected. Depending on the material used, when heat correction is adopted, the heating temperature should not exceed 900 °C, and then it should be naturally cooled.

3. Steel Component Welding

3.1. The specifications, models and performance of the welding materials should conform to the current national product standards and design requirements.

3.2. The welding material must be matched with the base metal, and should comply with the provisions of JGJ81 "Technical Regulations for Welding of Building Steel Structures".

3.3. The welders involved in the welding must be certified and put in the welding within the scope of their certificates.

3.4. The welding procedure qualification must be carried out before welding, and the welding process is determined according to the report.

3.5. For the welds of steel components, the full penetration welds required for design shall be inspected for internal defects, and ultrasonic and ray shall be used for flaw detection. The implementation standards and sampling ratio shall be implemented according to GB11345 and GB3323.

3.6. Weld surface defects: There should be no defects such as cracks and welds on the surface of ordinary welds; there should be no defects such as pores, slag inclusions, cracks in the pits, arc scratches, etc. on the surface of the second grade welds; There should be no defects such as undercut, unwelded, and root shrinkage etc, on the surface of first grade welds.

4. The Pre-assembly of Steel Components

The connection between high-strength bolts and ordinary bolts shall be checked by a hole-trimming device. When using a hole-operator with a diameter smaller than 1.0 mm, the pass rate shall not be less than 85%. When using a hole-operator that is 0.3 mm larger than the bolt diameter, The pass rate is 100%. It is strictly forbidden to use gas cutting and electric welding punching on site.

5. the Assembly of Steel Components

5.1. The truss of the crane beam and the crane beam shall be erected during inspection. After being supported at both ends, the water level gauge and the steel rule shall be inspected and shall not be scratched.

5.2. End milling accuracy, the length deviation of the component when the end is flattened is ±2.0mm, and the flatness of the milling plane is 0.3mm.

5.3. The outer dimensions of the steel components should be inspected in full and checked with a steel ruler.

6. The Installation Process of Single-layer Steel Structure

6.1. Installation of anchor bolts: Before the steel components arriving at the site, the civil company should has completed the construction according to the drawings. The specifications, axis, elevation and spacing of the anchor bolts have been accepted and qualified, and the anchor bolts have passed the retest. The concrete strength should meet the lifting requirements. The longitudinal and transverse centerlines of the steel columns on the bearing platform are all well-rebounded and have been re-qualified.

6.2. The center line of the steel column and the reference point of the elevation should be marked well, and then the steel column should be hoisted. If the factory is long, it should be installed from one end to the end of the construction joint. When there is support between the columns, it must be fully installed, and the secondary components such as the tie rods in roof should be installed together.

6.3. Correction after installation of steel column: The construction party is required to test the elevation and verticality of each steel column one by one according to the design and specification requirements. The method is as follows: using a level gauge to align the reference point to the elevation; using two theodolites to measure the verticality in two different directions until it is adjusted.

6.4. The installation sequence of the roof steel beam and the secondary members is the same as that of the steel column: it should be installed one by one. After the first steel beam and the second steel beam forming a stable structural unit, the four steel wires are used for symmetry fixed. After finishing, the crane can be moved away. Then the third and fourth steel beams are installed next to each other until all is completed.Only in this way, the safety accident can be avoided.

7. Fasteners

Fastener installation can be divided into ordinary fastener connection and high strength bolt connection. In the process of steel structure installation, the installation of this process should be carried out simultaneously. The control points are as follows:

7.1. Ordinary fasteners: They should meet the design requirements. Their quality assurance data have been checked. They should be tested according to the current national standard GB3098. Generally speaking, as long as the bolt length is tightened, two threads can be exposed.

7.2. High Strength Bolts: Before installation, according to the requirements of the drawings, the bolts of each specification are sampled and retested. Eight bolts of each specification are taken for tensile and torsional tests.

8. Surface Anticorrosion of Steel Structures

When all the steel members are welded, the necessary rust-proof treatment should be carried out on the surface of the steel members according to the design requirements. Its control focuses on:

8.1. Check the quality certification documents, Chinese marks and inspection reports of anticorrosive coatings products;

8.2. Surface treatment should be done according to 10% of the total number of components, not less than 3 pieces;

8.3. Coating should be carried out in layers. And after acceptance, the thickness of each layer should be uniform, which should meet the requirements of design and specifications.

8.4. When the coating is finished, the thickness of each component is inspected by a film thickness gauge. Five parts are inspected. Finally, the average thickness of the coating is calculated. The total thickness of the dry paint should be 150 micron outdoors and 125 micron indoors. The allowable deviation is -25 micron.

9. Fireproof Coatings for Steel Structures

9.1. Fireproof coatings shall be inspected for bond strength, tensile strength and other contents as required, and their product quality certification documents and inspection reports shall be inspected.

9.2. The surface of fire-retardant coatings must be cleaned up before painting. Layered coating should be carried out according to the fire-resistant limit designed by the drawings.

9.3. Use thickness gauge to test the coating of fire-retardant coatings. When it is a thin coated coating, it should meet the requirements of design fire-resistant limit. When it is a thick coated fire retardant coating, more than 80% of the area should meet the design requirements of the fire resistance limit. And the thickness of the thinnest place should not be less than 85% of the design requirements. (Thickness shall be in accordance with GB14907-2002 standard).

10. Pressed metal sheets for roofing

When the main structure is completed and accepted, the next step is the installation of roof panel. The general drawings only design the type and specification of the board. The specific construction is usually designed by the construction unit itself, and the detailed drawings should be confirmed by the original design unit before they can be put into use. The detailed drawings include detailed drawings of color steel plate, detailed structural treatment and large-scale expansion drawings of joints, etc. The construction difficulties are as follows:

10.1. Treatment of roof openings: There are many designs for roof fan openings of steel structure factory buildings. Although there are detailed drawings, if there are no good skilled workers, once they are not handled properly, the rain will leak. And the leaking points can not be found. They are always repaired and leaked again and again which brings adverse effects to production and also creates a bad impression to construction units. Therefore, this process is the focus of supervision and control.

10.2. Wall opening and 1.2m window sill edge-closing treatment: The key to the construction of window opening edge-closing is the treatment of the four corners of the hole. Once the treatment is not good, the rainwater will leak from the joint to the factory building. There is no more glue can guarantee no rain-leakage. The steel structure factory building is generally designed as a brick masonry around the outer wall 1.2m, and the outer wall plate is fixed on the top ring beam and connected with the wall purlin. If the edge of the part is not made into an outward slope and the joint glue is not good, the rainwater on the wall will leak from the joint to the inner wall which will cause all the paint on the inner wall to fall off especially when it is windy and rainy, . Even if the leak point is found and can not be repaired. The outer wall board can only be removed for maintenance. Maintenance costs are higher and maintenance time is longer. This is also the focus of supervision control.

10.3. In addition, the treatment of roof edge closure is also the key point. Rainfall leakage can not be found. Although maintenance is more convenient, it should also be controlled.

Wan Jin Long Group is engaged in various types of housing construction projects, such as steel structure workshop construction design, container house, prefab house and so on. Wan JinLong is a company with 20 years experience in steel structure engineering. It integrates steel structure design, processing, production and installation to provide you with one-stop construction services. Professional work has always been our purpose. We will be able to build high-quality steel construction projects for you.