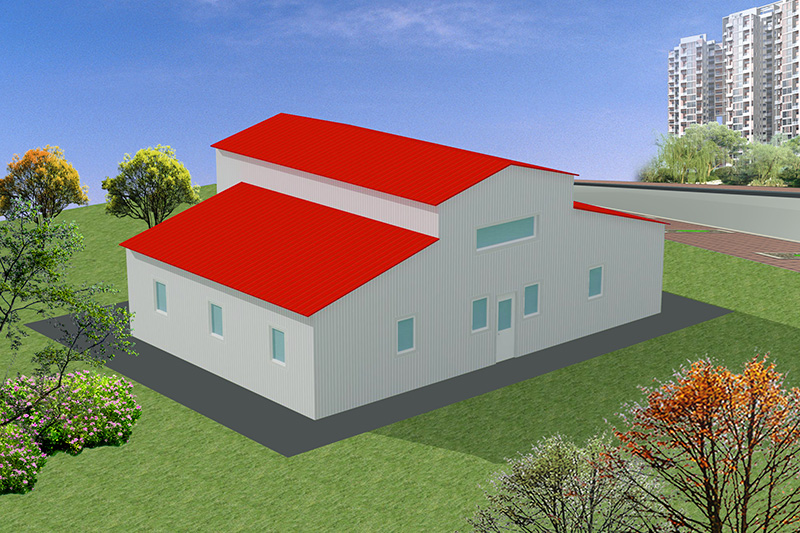

Project Name: Mongolia Locomotive Maintenance Workshop Project

The project utilizes a steel structure frame and new building panels as its primary design. The main structure consists of two connected buildings: a maintenance workshop and an office. The building adopts a large-span portal steel structure system with a eaves height of 12m-14m, a column distance of 6m, and a span of 20-34m.It is divided into two independent units, of which the office is designed as a two-floor building, using a steel structure floor concrete pouring scheme.

All steel components are prefabricated in the factory (including drilling, welding, and anti-corrosion painting).Only bolt connection and hoisting are required on site. The production and processing cycle is shortened to 25 days, which is 50% less than the traditional workshop construction cycle.

Anti-corrosion and fireproofing treatment: The steel structure surface adopts a multi-layer anti-corrosion system of "sandblasting rust removal (Sa2.5 level) + epoxy zinc-rich primer (80μm) + epoxy micaceous iron intermediate paint (60μm) + polyurethane topcoat (40μm)", with salt spray resistance of more than 1,500 hours, suitable for the humid and oily environment in the workshop.

| Project Name | Mongolia Locomotive Maintenance Workshop Project |

|---|---|

| Structure System | Steel Structure |

| Quantity | About 300 tons of main structure + 5000㎡ roof and exterior wall enclosure |

| Steel Frame | Steel Column, Steel beam: Q355B material |

| paint | grey (180μm) |

| sandwich panel | The roof and walls are made of polyurethane edge-sealed rock wool sandwich panel. The roof is 200mm thick RAL7012; the wall is 150mm RAL7035; the parapet is set to 100mm RAL7012 |

| Features | 1. Welded steel, H-beam |

| 2. beautiful and practical, reasonable cost. | |

| 3. easy to move, recycling without pollution. |