Project Name: Papua New Guinea Northern Province Parliament Building Project

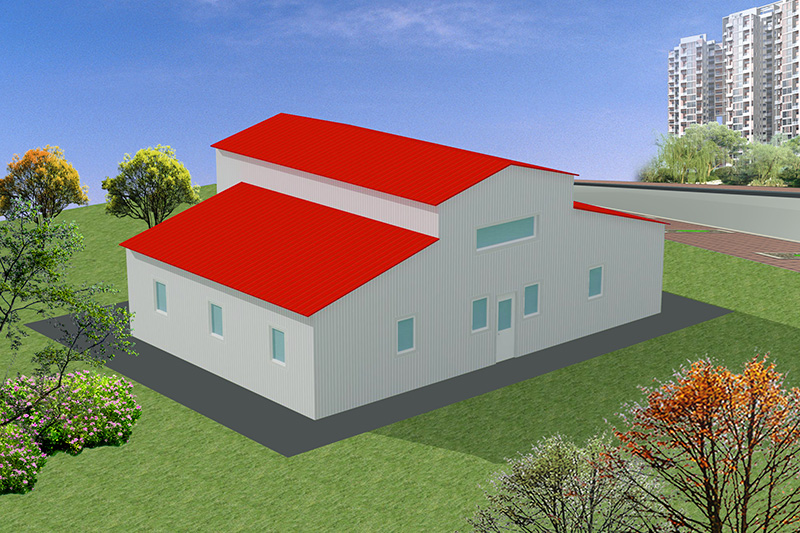

This project is the core government building in Papua New Guinea's Northern Province. It is positioned as a landmark venue that integrates parliamentary meetings, administrative offices, and public services. It includes a large main conference hall, a conference reception center, small and medium-sized meeting rooms, offices, equipment rooms, municipal services, and other related supporting facilities.The building area is approximately 1,500 square meters, divided into two floors, with a steel structure as the core load-bearing system, taking into account the solemnity of government buildings and the expression of regional culture, while adapting to the local humid and rainy climate characteristics.

1. Design of the main steel structure system

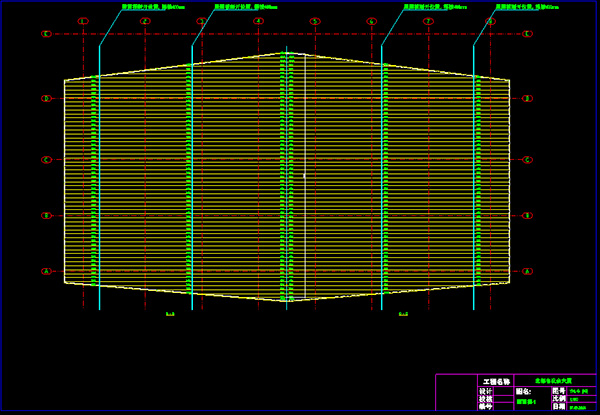

The main body of the project adopts a steel frame, and the main profile is made of Q355B low-alloy high-strength steel (adapting to the toughness requirements of tropical humid environments). The main structure adopts welded H-shaped steel, and the secondary beams are C-shaped steel 275g galvanized purlins. The seismic fortification intensity of the overall structure is set at level VII according to local regulations, and the wind load value is 0.8kN/㎡, ensuring the safety of the building under the climatic conditions of frequent tropical storms.

The column spacing in the core office area is controlled at 6-8m, creating an open and unobstructed meeting space and office environment. The factory prefabrication rate of steel structure components reaches 95%, reducing the frequency of on-site construction being affected by the rainy season and shortening the construction period.

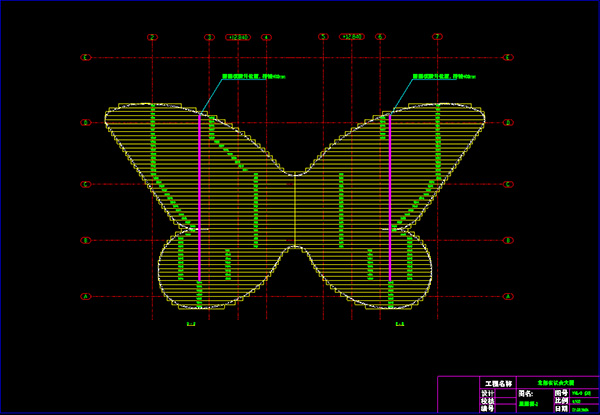

2. Unique butterfly-shaped roof and roofing craftsmanship

The roof is the core design highlight of the project. Inspired by the "tropical butterfly wings", it is a butterfly-shaped steel structure roof: the total span of the two wings is 45m. The skeleton is formed by welding curved steel. The curvature of the flange is precisely controlled through 3D modeling to ensure the symmetry of the "butterfly wings" on both sides. It not only symbolizes the ecological vitality of the Northern Province, but also strengthens the iconic identity of the government building.

The roofing system utilizes an on-site composite process combining aluminum-magnesium-manganese roof panels, thermal insulation, and stainless steel mesh. The outer layer features 1.0mm-thick 3004 aluminum-magnesium-manganese alloy plates (weather-resistant and corrosion-resistant in humid environments) with standing seams (65mm high for excellent waterproofing). The middle layer is insulated with 100mm-thick centrifugal glass wool (thermal conductivity ≤0.042W/(m·K) to meet indoor temperature requirements). A bottom layer of 304 stainless steel mesh protects the insulation from moisture and clumps, while also providing fire protection. These three layers are laid sequentially on-site and mechanically secured, forming an integrated roofing system that combines waterproofing, thermal insulation, and moisture-proofing, adapting to the local average annual humidity of over 85%.

| Project Name | Papua New Guinea Northern Province Parliament Building Project |

|---|---|

| Structure System | Steel Structure |

| Quantity | Approximately 1500㎡ floor area + 4500㎡ roof aluminum plate + 1800m floor decking |

| Steel Frame | Steel Column, Steel beam: Q355B material |

| paint | Inorganic zinc silicate primer (50μm) |

| roof system | he roof is made of aluminum-magnesium-manganese plate 430, and the combination of emerald green (RAL6001) and pastel blue (RAL5024) creates a butterfly pattern. |

| Features | 1. H-shaped steel, curved beam, 275g galvanized C-shaped steel |

| 2. beautiful and practical, reasonable cost. | |

| 3. easy to move, recycling without pollution. |